Low-capacity shaft type torque transducer newly released!

One more choice for your low-capacity applications.

Industry-leading fast response!

- Our minimum-capacity category!

- 25,000rpm high-speed rotation!

- High zero-point stability!

Optical transmission little affected by disturbances.

Much more reliable measurements achievable!

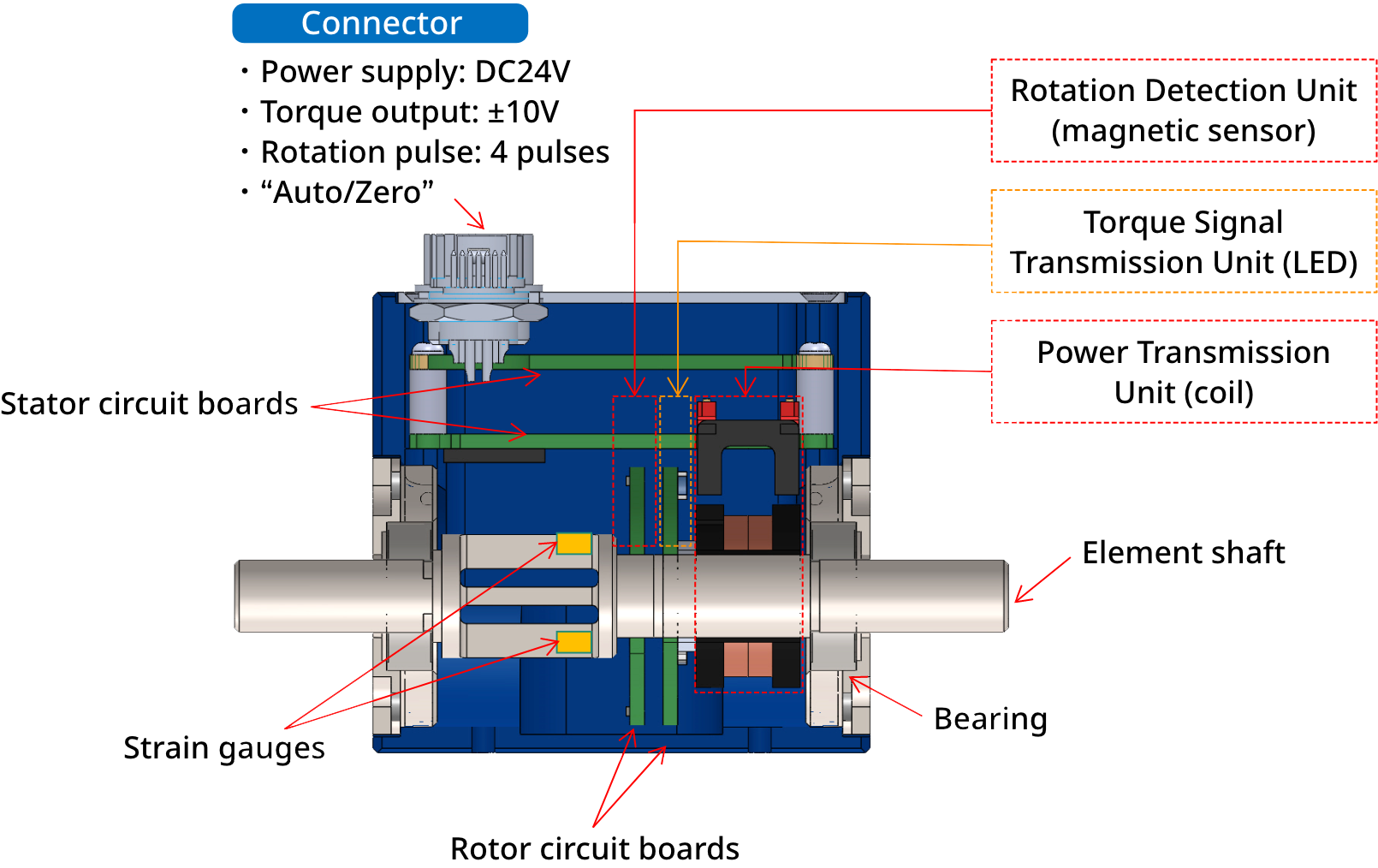

Conventional rotary torque transducers have been of non-contact signal transmission type using electromagnetic induction and slip ring.

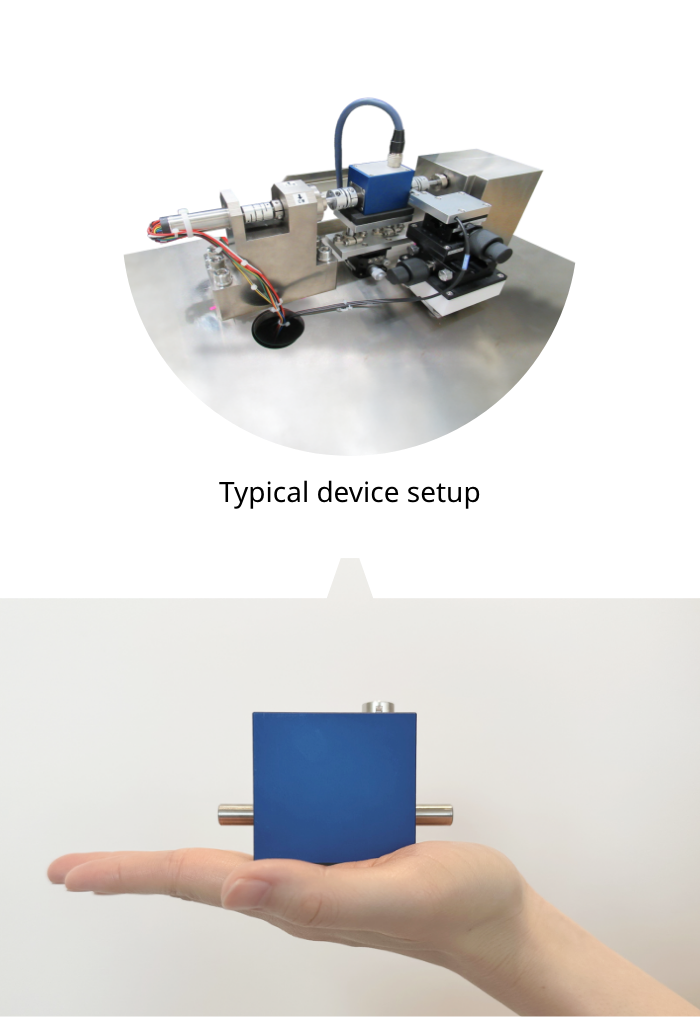

We have come up with the TMRS shaft type torque transducer, adopting optical transmission, to broaden our product lineup.

Our engineering staff have improved the processing accuracy and reviewed the strain gauge setup and control technology.

Compared to existing models, the TMRS has achieved some outstanding features; low capacity, high accuracy, high rotation and fast response.

Technically precise, highly durable, flexibly applicable!

High precision

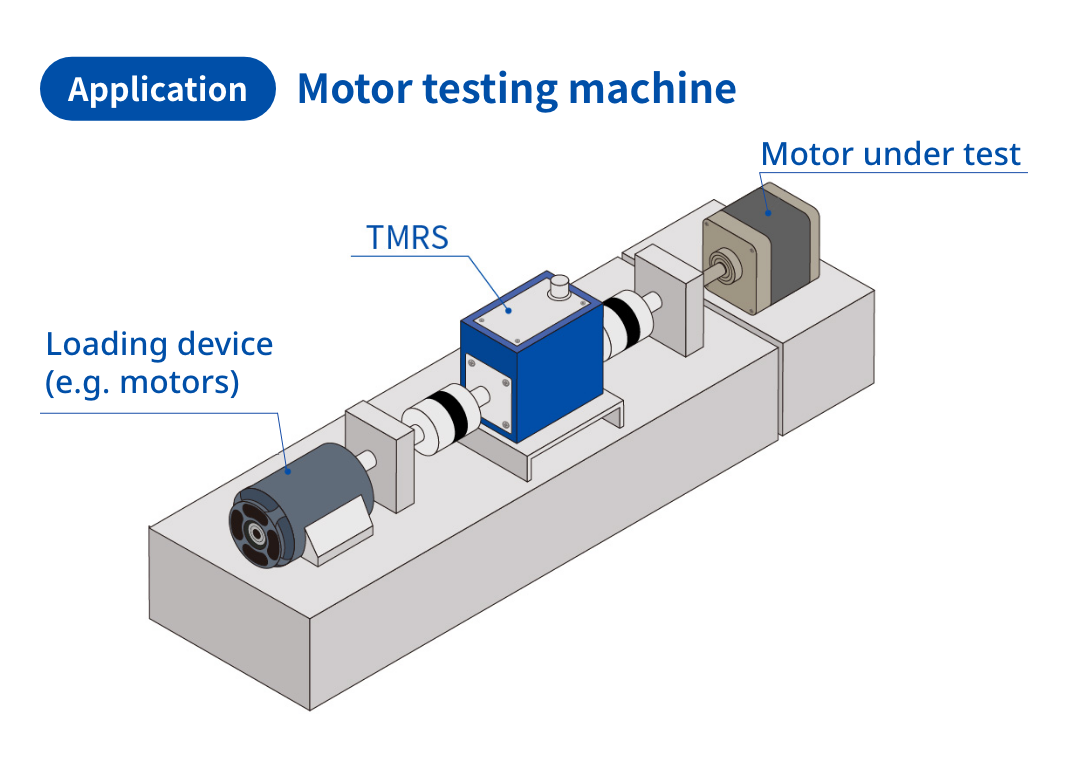

Industry-leading responsiveness to support R&D activities! Sensing even momentary torque fluctuations with 6-kHz response performance!

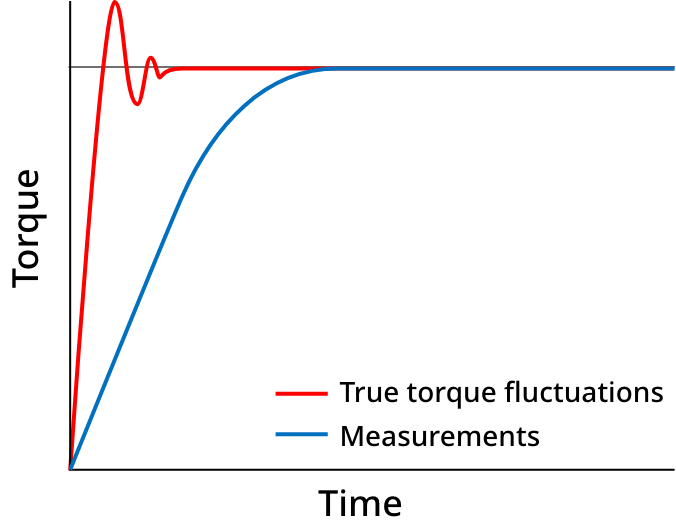

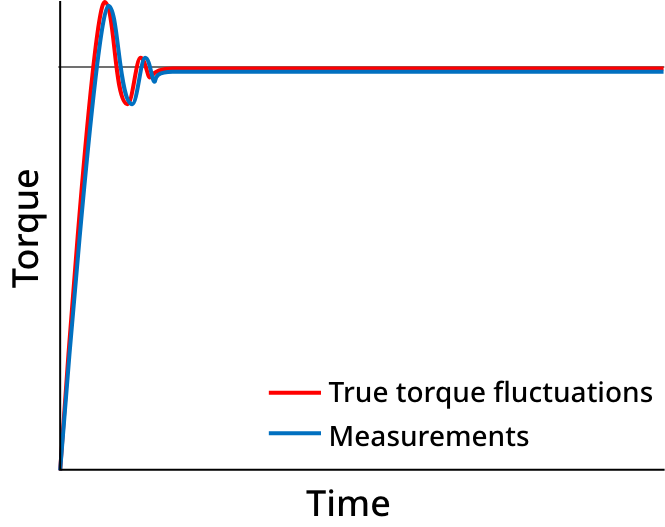

"Responsiveness" is crucially important in measurement.

This is a key factor, among others, in applications and processes with rapid torque fluctuations.

Thanks to its innovative responsiveness (6 kHz), the TMRS can accurately detect instantaneous torque fluctuations

and make data available in real time. This advantage makes for accurate characteristic evaluation of multipole motors, for instance.

High-speed response at the 6-kHz analog bandwidth

Sensors with slow

response time ...

Not sensitive for correct measure of

instantaneous torque fluctuations.

Sensors with quick

response time ...

Very sensitive for correct measure of instantaneous torque fluctuations.

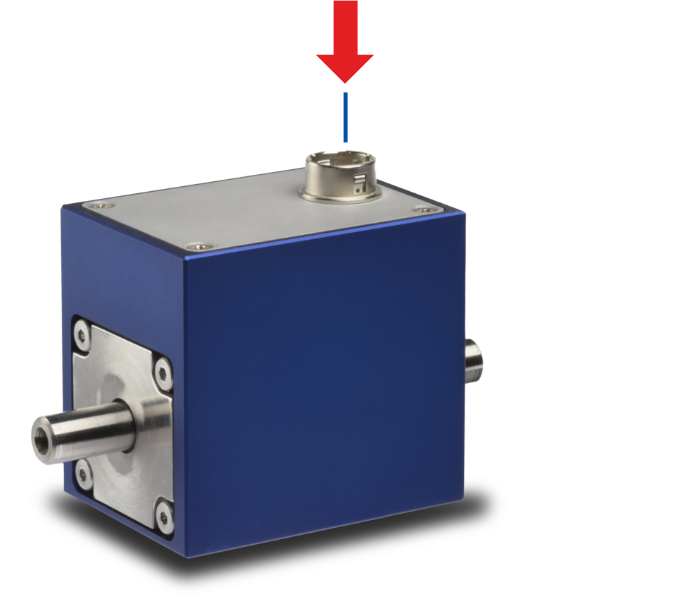

What’s more, the brainchild comes with higher rpm, better zero-point stability and less zero shift by rotation.

In measuring torques, it is very important to accurately maintain zero torque even during high-speed rotation.

Thanks to its precise shaft machining, the TMRS provides for fast spinning as high as 25,000 rpm, yet its zero-point stability is great

and its zero shift by rotation is minimized.

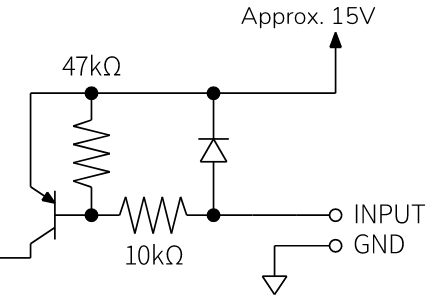

─ “Auto/Zero” function for zero-point correction ─

The “Auto/Zero” function employs an external ZERO signal to compensate for an output deviation at no load

depending on installation conditions.

ZERO signal

A/Z ON: Pulse signal input to turn on A/Z.

A/Z OFF: Pulse signal input to turn off A/Z.

Specific cable (RC041-*M) [sold separately] specifications

![Specific cable (RC041-*M) [sold separately] specifications](/en/promotion/xducr-tmrs/images/img04.png)

Pin arrangement & wiring for specific cable (RC041-*M) [sold separately]

![専用ケーブル(RC041-*M) [別売品] ピン配置・配線図](/en/promotion/xducr-tmrs/images/img05.png)

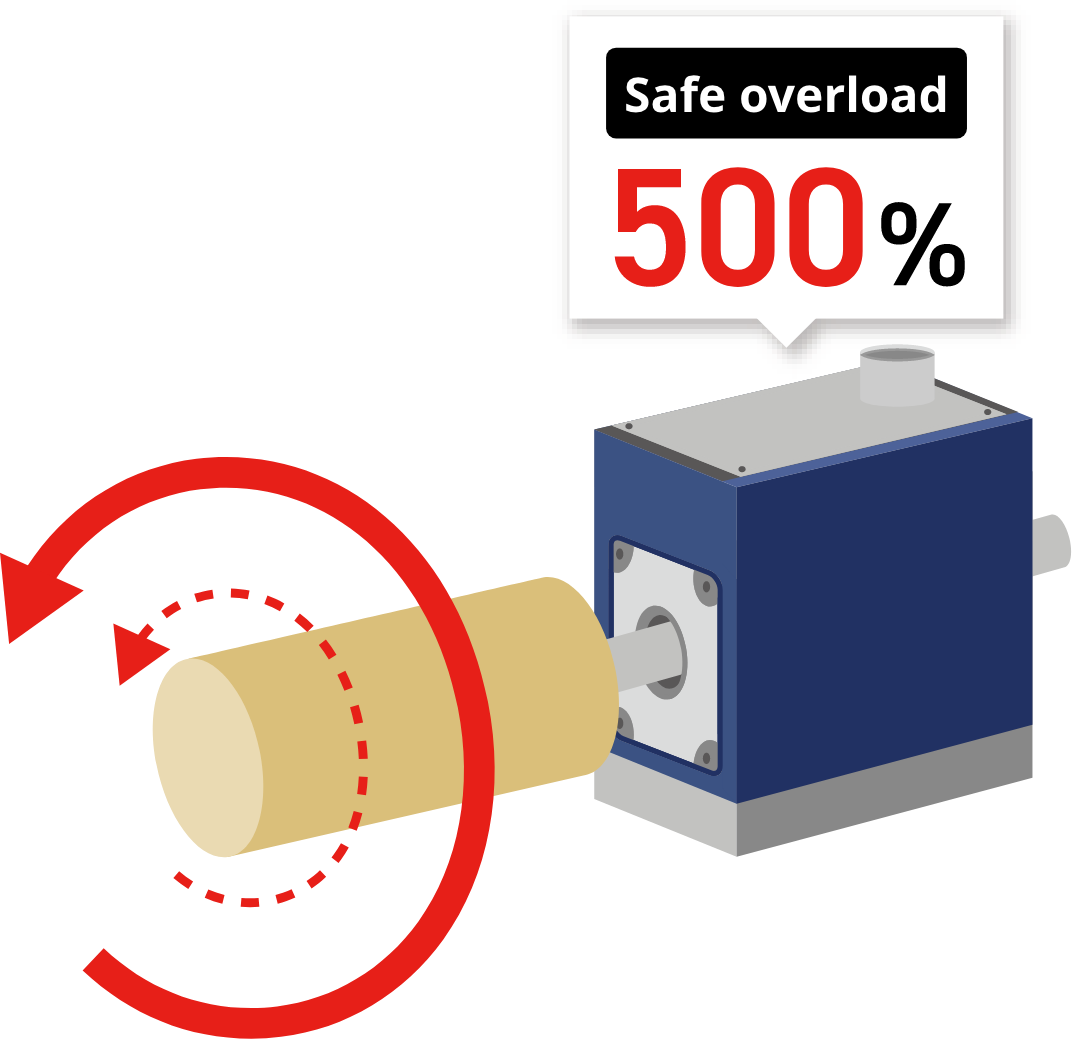

High durability

Permissible overload is as high as 500%F.S.

of the rated capacity.

Torque transducers must be able to handle unexpected spikes in torque that would occur at the start and stop of a machine.

The TMRS is robustly structured to withstand impact torques 5 times higher than the rated capacity. Even if a torque exceeding the rated capacity is temporarily generated, the torque transducer is never damaged and the measurement accuracy can be maintained.

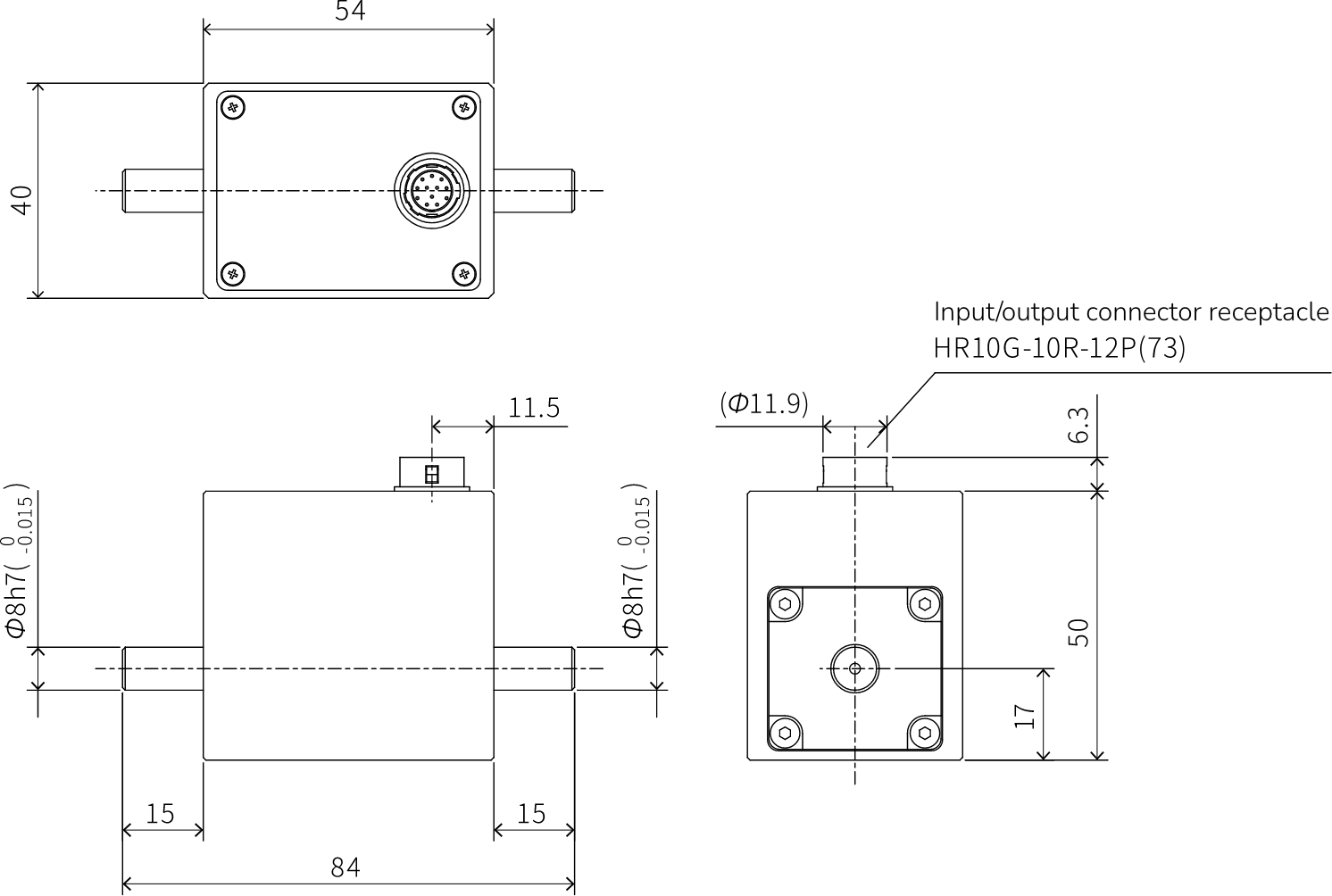

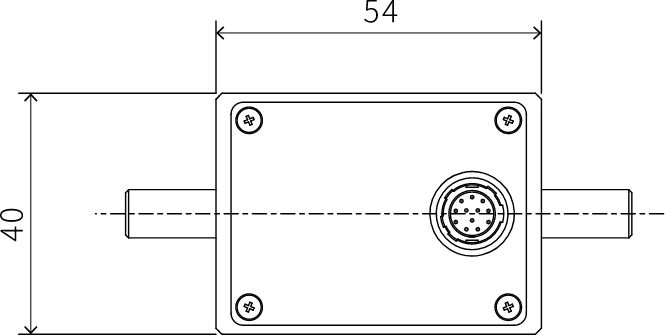

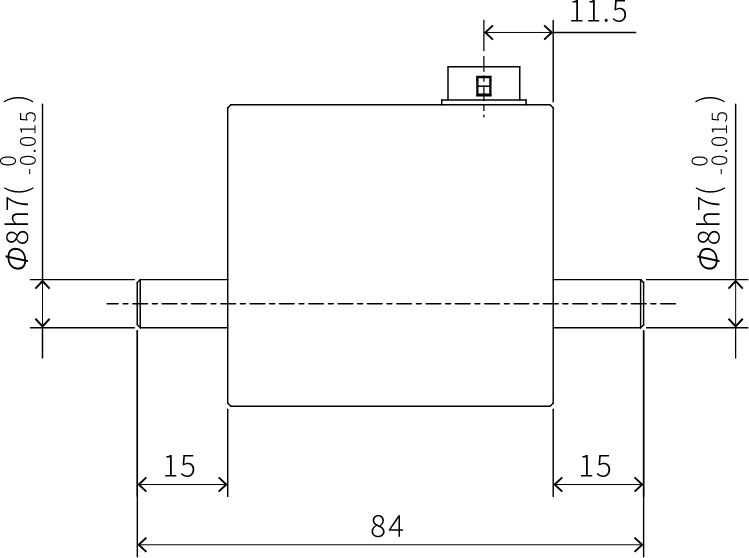

High adaptability

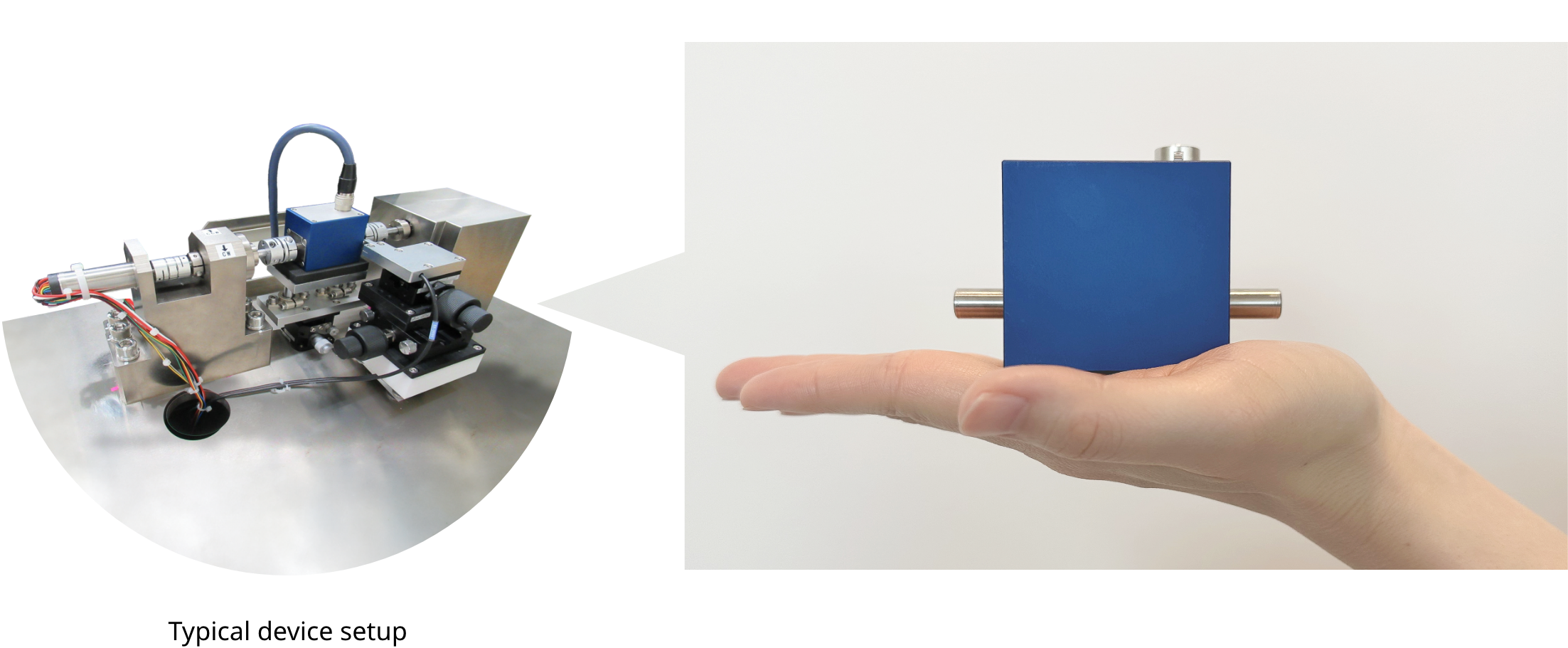

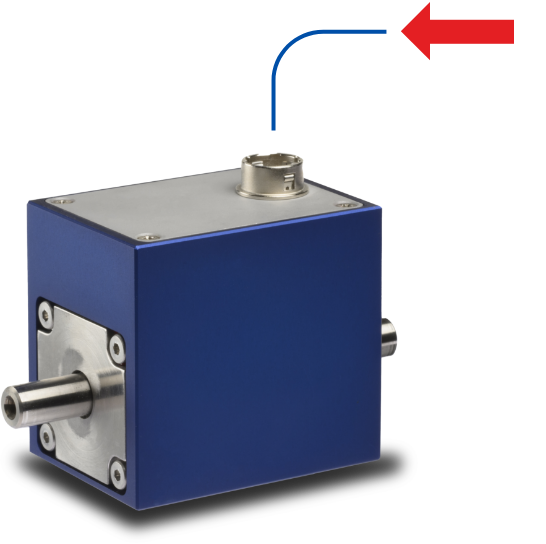

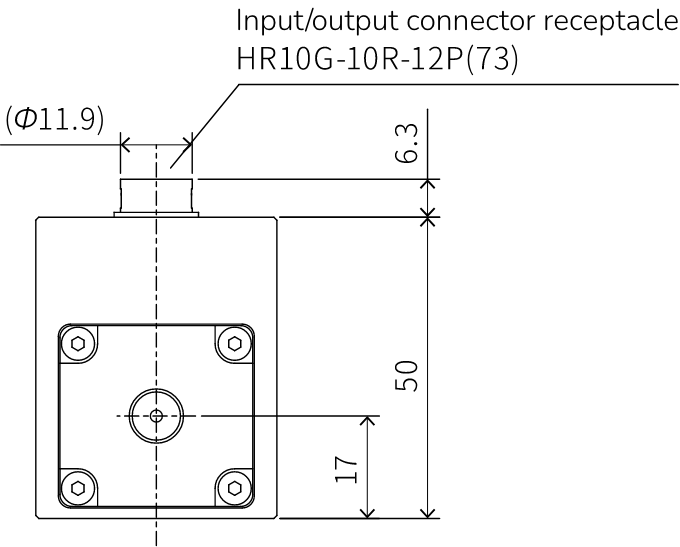

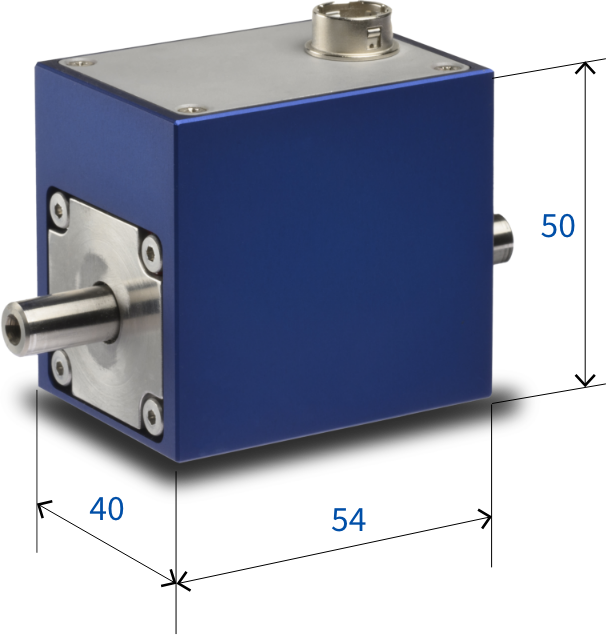

The compact design helps to fit in small spaces of industrial equipment more flexibly.

Compared to conventional models, the smaller torque transducer is easy to mount into systems and test equipment.

In a nutshell, the device is also suitable for use in limited spaces.

The small device can fit even in narrow shaft-to-shaft spaces.