- Miniature & small ball bearings

Ideal thermal control supports by Ball bearings

Best Practice

Ball bearings for automotive e-compressor

Ideal thermal control

supports by Ball bearings

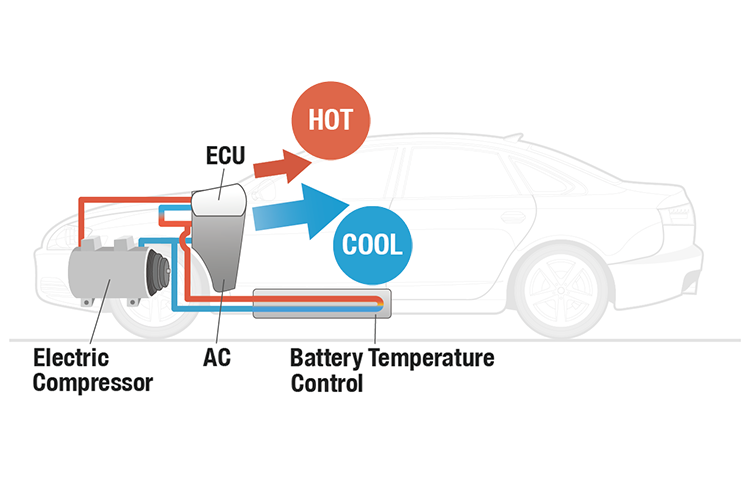

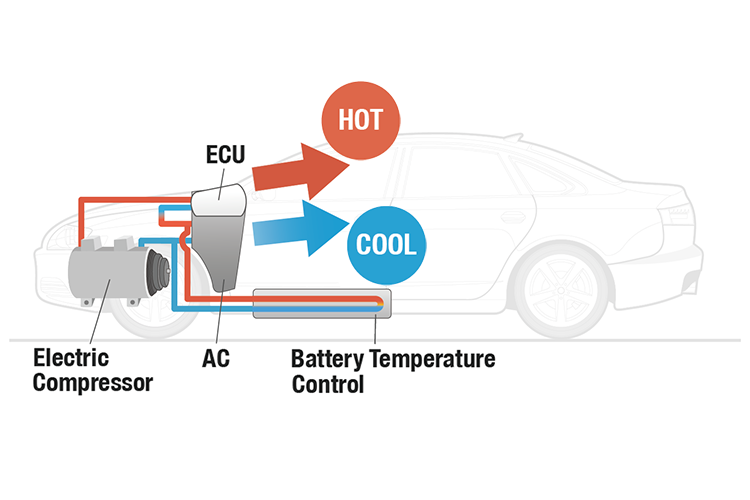

Hybrid and electric vehicles, which are rapidly gaining popularity in recent years, require a wide range of thermal management systems, including not only cabin air conditioning but also temperature control of lithium-ion batteries.

Our ball bearings are used in highly efficient electric compressors, which are vital part for thermal management.

Problems

With the spread of hybrid and electric vehicles, compressors for car air conditioners are changing from swash plate type driven by engine power via a timing belt to scroll type driven by a motor, which requires more efficient refrigerant compression with lower vibration.

Solutions

Our ball bearings now expand size lineup compared to our conventional offerings, minimizing rotational torque in e-compressors and achieving smooth rotation.

Furthermore, our retainer rings support by high-precision for the orbital scroll's rotation.

How car air conditioners work and the role of the compressor

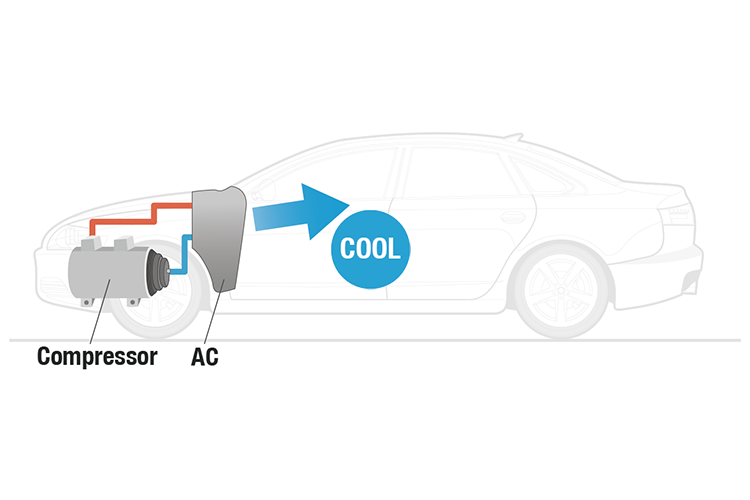

Car air conditioners have the important function of regulating the cabin temperature not only during the hot summer months, but also during various weather conditions, such as rainy days and cold winter days. In particular, the defroster function, which removes fogging from the window glass, is an essential element for safe driving. The cooling function of car air conditioners is based on the principle of the “refrigeration cycle. This refrigeration cycle utilizes the physical property of gases and liquids that their temperature rises when they are compressed and decreases when they are suddenly released (expanded) from their compressed state.

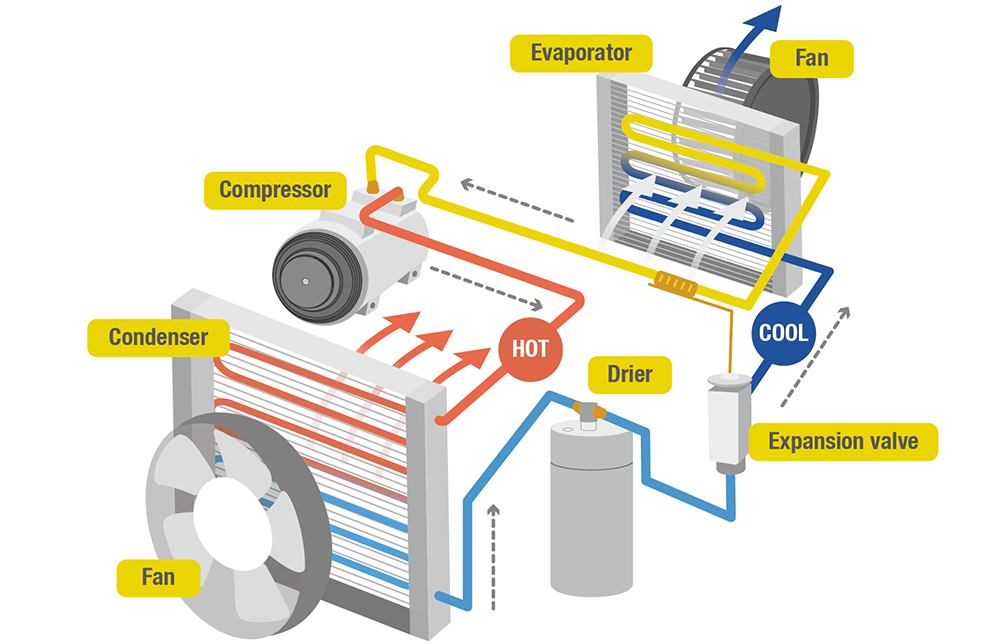

The refrigeration cycle used in car air conditioners consists of four processes that are repeated by the refrigerant: compression, condensation, expansion, and evaporation. First, a compressor compresses the refrigerant, converting it into a hot, high-pressure gas. Next, the hot, high-pressure gas is sent to a condenser, where it is cooled and condensed through heat exchange with the outside air. The low-temperature, high-pressure refrigerant is then sent to the evaporator, where it undergoes heat exchange (evaporation) with the air blown into the cabin. By repeating this cycle, the temperature inside the cabin can be efficiently regulated.

The compressor plays the role of “compression” in this refrigeration cycle. When the compressor compresses the refrigerant, it produces a hot, high-pressure gas that enables the next process, condensation. The performance of the compressor greatly affects the efficiency of the entire refrigeration cycle, making it an extremely important component.

Automotive electrification and electric compressors

Conventional car air conditioner compressors were rotated by engine power via belts or other means. However, with the increasing demand for smaller engines and improved fuel efficiency, it has become difficult to achieve low fuel consumption with conventional compressors that use engine power. In particular, hybrid vehicles have shorter engine runtimes, which causes problems when conventional compressors cannot be used for car air-conditioning.

In electric vehicles, the compressor's electrification is essential to the use of the car air conditioner, since the vehicle is not equipped with an engine in the first place. Since electric compressors do not depend on engine power, but operate on electricity supplied by the battery, car air conditioners can be used stably regardless of the engine's running time.

In addition, electric compressors play an important role not only in regulating cabin temperature, but also in thermal management to cool batteries and other onboard electronic devices that can easily become hot. In increasingly electrified vehicles, electric compressors have become an indispensable component, and their role is expanding.

ICE

- Cabin cooling

HEV

- Cabin cooling

- Cabin heating support

- Thermal control for Li-ion battery

- hermal control for traction motor

- ECU cooling

BEV

- Cabin cooling

- Cabin heating

- Thermal control for Li-ion battery

- Thermal control for traction motor

- ECU cooling

Ball bearings and electric compressors

The electric compressor uses a scroll type compressor consisting of a fixed scroll and a orbital scroll. This scroll type compressor is capable of continuous compression and discharge and achieves excellent efficiency. However, the gap between the fixed and orbital scrolls must be extremely small, requiring high machining and assembly precision. For this reason, ball bearings are used in the motor bearings to support the motion of the orbital scroll with high precision. Ball bearings are essential components to minimize friction and ensure smooth rotation.

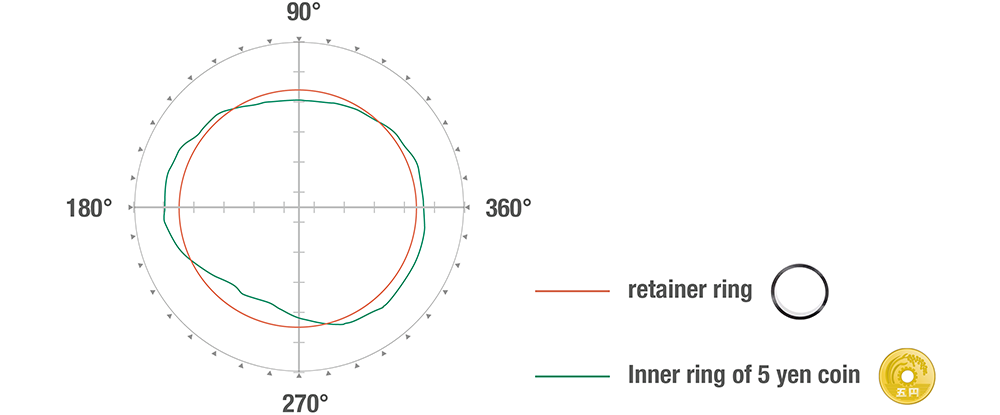

In order to prevent the orbital scroll from spinning and maintain excellent compression efficiency, special retainer rings are used that are converted from ball bearing parts. Retainer rings hold the orbital scroll in the proper position and support stable motion.

Our ball bearings and retaining rings have improved the roughness of the grooves in which the balls roll using our ultra-precision machining technology, and they also have extremely high roundness. This contributes to the excellent compression efficiency of electric compressors.

For product-related inquiries, please contact us using the form below.

Products

Miniature & small ball bearings

Engineering Information

Technical information by product [Bearings]

Product Catalog

Miniature & small ball bearing Product Catalog

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.