- Precision mechanical components

Solution to Precision Mechanical Assembly Challenges -Cartridge Bearing Case Study-

As specialists in bearings, we can make motors run quieter and long lasting through meticulous preload management and assembly/bonding know-how.

Solution to Precision Mechanical Assembly Challenges

Cartridge Bearing Case Study

Contributing to motor quietness and extended service life through meticulous preload management and assembly/bonding expertise

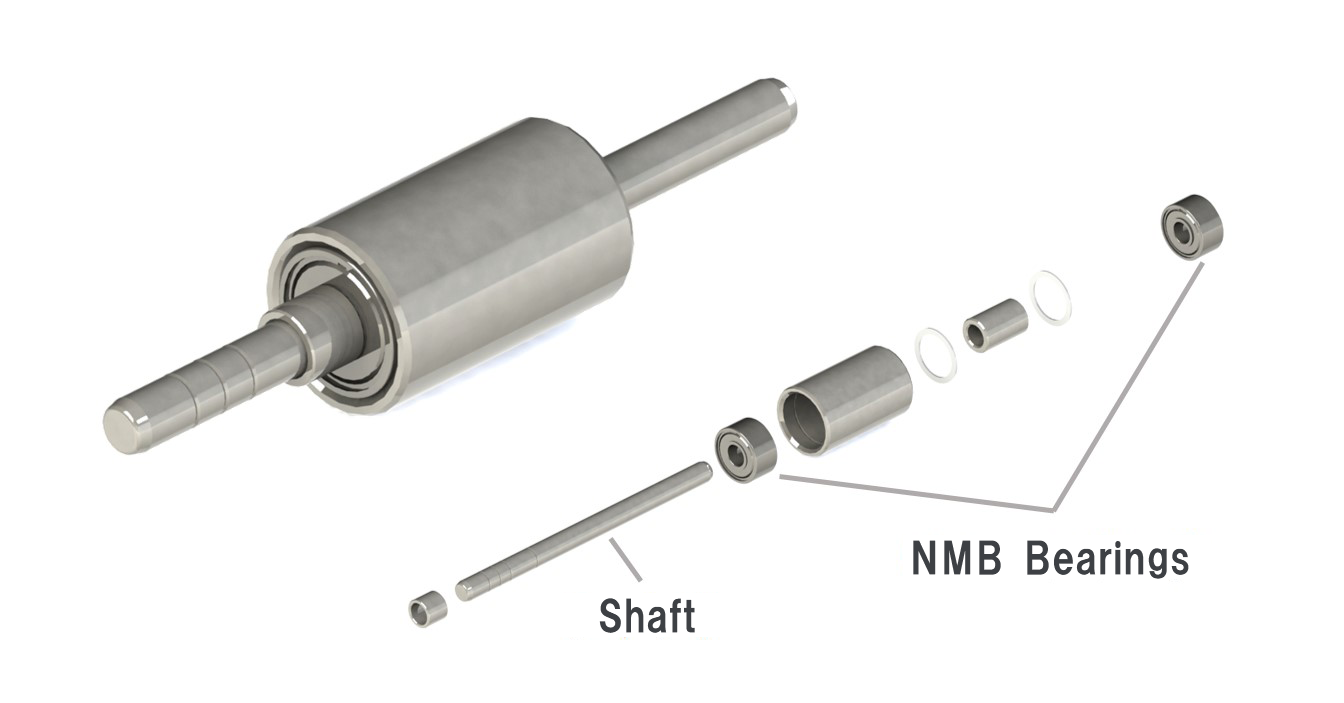

Precision mechanical assembly for cartridge bearings

Cartridge bearings comprising our proprietary ultra-precision ball bearings, assembled with our high-precision machined shafts and housings, and delivered with appropriate applied preload to customers.

MinebeaMitsumi has accumulated extensive knowledge over the years. Internally we could control the delicate clearance of our bearings to apply the optimal preload and utilize assembly and bonding techniques to minimize shaft runout and play. Such high level of precision even on assemblies using tiny bearings with outer diameters of just 4 - 5mm are achievable.

What's so great about cartridge bearings?

Meticulous preload management significantly improves runout and play

At Precision Mechanical Assembly, our strength lies in assembly techniques that fully utilise the inherent internal clearance within ball bearings, known as “preload”.

Axial load applied to bearings eliminate internal clearance to obtain rigidity and suppresses runout. However, managing this preload is extremely challenging and requires extensive experience and expertise. If the preload is too high, rigidity increases, but it can also lead to increased noise and reduced lifespan. Conversely, if it's too low, the rigidity becomes insufficient, runout and play become excessive.

Leveraging MinebeaMitsumi's over 70 years of bearing manufacturing and handling expertise, our cartridge bearings feature precise preload management tailored to each bearing's unique characteristics. As demonstrated in the video, this significantly reduces shaft runout and play, ultimately contributing to improved performance in motors and end products – enhancing service life, acoustic characteristics, and rotational accuracy.

Our cartridge bearings allow preload specification in increments of 0.5N.

World's No. 1* High-Precision Assembly and Bonding Technology Ensures Stable Supply of High-Quality Products

Developed through comprehensive knowledge of bearing internal characteristics, our design, assembly, and bonding techniques enable the assurance of high-precision shaft alignment.

Managing bearings and components with outer diameters of just a few millimetres is not only labour-intensive, but their intricate assembly and bonding require skilled craftsmanship, demanding considerable time for technician development.

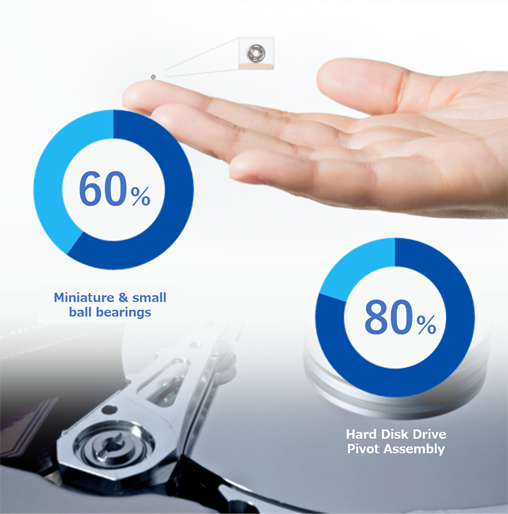

MinebeaMitsumi holds the top global market share* of over 60% in miniature ball bearings with outer diameters lesser than 22mm. Our product lineup includes the world's smallest* ball bearing with an outer diameter of 1.5mm and the world's smallest* stepping motor with an outer diameter of 3.3mm. This showcases our capability to provide a stable supply of high-quality products, handling sub-micron precision machining, assembly, and bonding.

Our technological expertise, including our preload management, has earned us a strong reputation for high-precision bearing assemblies for hard disk drives, where we currently hold an 80% global market share.

-

*Based on our research.

Pick Up! ──

Introducing Precision Mechanical Components (PMC):

mechanical parts and sub-assembly products that maximize bearing performance.

Leveraging the technical expertise of a bearing specialist, including ultra-precision machining technology and assembly know-how, PMC products bring out the full potential of bearings. They address critical challenges related to rotational accuracy, lifespan, and vibration.

Please feel free to contact us

Related page

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.