CASES

MinebeaMitsumi’s integrated mold sensing system

Case example of introducing the system

Reducing inspection costs

By introducing the integrated mold sensing system,

the manufacturer became able to detect unpredictable short shots and

consequently changed 100% visual inspection to sampling inspection.

This led to a reduction in manhours and costs required for inspection.

- Background of introducing the mold cavity pressure measurement system

The manufacturer used to control the quality of the products it manufactures with molding machines without using sensors.

To reinforce the quality control and provide high-quality products to customers,

the manufacturer introduced the packaged system.

- Effect of introducing the system

-

-

BEFORE

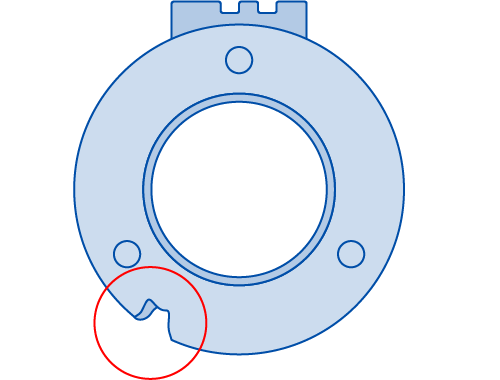

Short shot resulting in

incomplete perimeterPerforming 100% visual inspections to check for short shots

There were events in which short shots occurred unexpectedly during molding and resulted in molded products with incomplete perimeters. The manufacturer was unable to prevent such unpredictable short shots from occurring and had to visually inspect all finished molded products and sort out defective ones.

-

AFTER

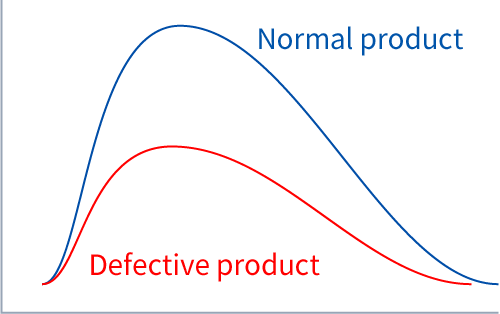

Detected from

cavity pressure waveformSetting the system to detect defective products and sort them out automatically

Changing 100% visual inspection to sampling inspectionAfter introducing the integrated mold sensing system, the manufacturer measured pressures in molds by using cavity pressure sensors and found that the cavity pressure waveform of a product with a short shot looks different from that of a normal product. The manufacturer became able to reliably detect short shots and sort out defective products, which allowed them to review their inspection process. This led to a cost reduction of about 8.5 million yen.

Example Number of inspectors(12-day work) Daily mean Labor cost(12-day work) Daily mean Before introducing the system 168 14 ¥545,976 ¥45,498 After introducing the system 81 -87 -52%

6.75 ¥263,244 -¥282,732 -52%

¥21,937 Cost reduced by

about 8.5 million yen

a year -