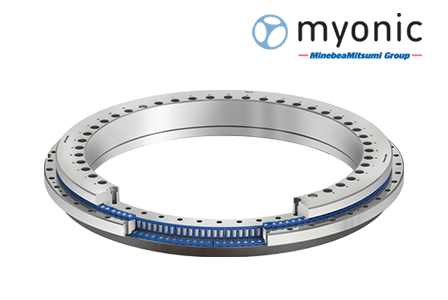

These bearings are designed for medical diagnostic equipment such as X-ray machines and computed tomography (CT) scanners.

They are capable of operating in harsh environments such as vacuum and high temperatures, and are characterized by high load capacity, long lifespan, low vibration, and low noise.

Applications

Medical X-ray Inspection Equipment

Custom

The ball bearing system developed by myonic ensures highly accurate, low-loss and vibration-free running in every position despite temperatures of up to 550°C. Bearing flange and housing are designed according to customer request. Due to our great knowledge by being close to our customers we understand their applications and can apply this experience into ever-improving products.

For product-related inquiries, please contact us using the form below.

Custom Case

Diagnostics / Mammography

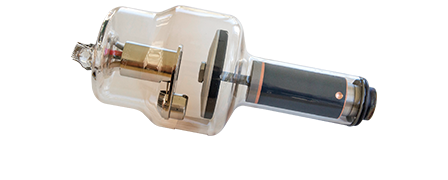

In X-ray imaging, high power and very short exposure times are used to avoid quality degradation due to patient movement during the procedure. The rotating anode technology, which disperses heat by rotating the target (anode), enables the production of high-performance and long-lasting X-ray tubes.

Mammography is used for the early detection of breast cancer in women without signs or symptoms of breast disease, as well as for diagnosing breast diseases in women who have symptoms such as lumps or pain.

myonic's X-ray tube bearings excel in quiet operation and low vibration, which helps reduce stress for patients undergoing the procedure.

The X-ray tube bearings for mammography enable the capture of hundreds of thousands of mammograms,significantly contributing to the eradication of breast cancer.

Main Specifications

| High vacuum | 10-7Pa |

|---|---|

| High temperature | up to 550℃ |

| Load Carrying Capacity | Rotating Mass < 1.5kg |

| G-forces | 0g |

| Design | Thermal Compensating / pre-loaded |

| Bearing Material | High temperature tool steel |

| Ball Material | High temperature tool steel |

| Housing Material | Stainless Steel |

| Speed Range | up to 10800rpm |

| Lubrication | dry film lubrication like Pb / Ag |

| Noise Specification | < 55 dBA with lead lubrication |

| Vibration | Low Vibration |

| Characteristics | Electrical conductivity, high voltage |

Mid-CT / vascular

Computed Tomography (CT) is a special form of X-ray that provides much more detailed images than conventional X-rays. CT uses specialized hardware and software to create highly accurate 3D images and cross-sectional images of various parts of the body. CT scans are used for diagnosing conditions such as strokes and hemorrhages, locating lung tumors, abdominal tumors, and inflammations, as well as for detecting fractures and vascular issues.

X-ray tube bearings for intermediate CT/vascular applications rotate around the patient up to 4 times

per second.

myonic's X-ray tube bearings provide high precision rotation and low noise in intermediate CT

applications.

Main Specifications

| High vacuum | 10-7Pa |

|---|---|

| High temperature | up to 550℃ |

| Load Carrying Capacity | Rotating Mass < 4kg |

| G-forces | 6g |

| Design | Thermal Compensating / pre-loaded |

| Bearing Material | High temperature tool steel |

| Ball Material | High temperature tool steel |

| Housing Material | Stainless Steel / copper-based metal |

| Speed Range | up to 10800rpm |

| Lubrication | dry film lubrication like Pb / Ag |

| Noise Specification | < 65 dBA with lead lubrication |

| Vibration | Low Vibration |

| Characteristics | Electrical conductivity, high voltage |

High-end CT

High-performance CT X-ray tube bearings rotate around the patient at a frequency of up to 4 times per second to generate multiple images.

This subjects the high-performance CT X-ray tube bearings to lateral accelerations equivalent to

50 times the force of gravity.

Simultaneously, the rotating anode spins around its own axis at up to 10,000 rpm.

The rotating anode must rotate with minimal vibration and noise. The high-performance CT X-ray tube bearings designed for this application achieve low vibration and quiet operation, and are capable of operating at bearing temperatures up to 550°C and in high vacuum conditions.

At myonic, we work closely with our customers to provide custom solutions that are optimal for their applications.

Main Specifications

| High vacuum | 10-7Pa |

|---|---|

| High temperature | up to 550℃ |

| Load Carrying Capacity | Rotating Mass < 6kg |

| G-forces | up to 50g |

| Design | Thermal Compensating / pre-loaded |

| Bearing Material | High temperature tool steel |

| Ball Material | High temperature tool steel |

| Housing Material | Stainless Steel / copper-based metal |

| Speed Range | up to 10800rpm |

| Lubrication | dry film lubrication like Pb / Ag |

| Noise Specification | < 65 dBA with lead lubrication |

| Vibration | Low Vibration |

| Characteristics | Electrical conductivity, high voltage |

Technical Support

The bearing flange and housing can be designed to meet your specific requirements.

We have extensive knowledge and can provide support in the following areas, so please feel free to consult with

us.

-

Rotor Dynamic Analysis – FFT analysis

-

Calculation of critical frequency

-

Bearing analysis

For product-related inquiries, please contact us using the form below.

About myonic

myonic was established in 1936 as RMB SA and merged with MinebeaMitsumi in 2009. With manufacturing facilities in Germany and the Czech Republic, Myonic specializes in the production of ultra-small ball bearings for the high-precision dental and medical equipment markets, as well as high-rigidity bearings for machine tools, based on its advanced precision bearing manufacturing technology. Due to its high quality, myonic has gained significant trust worldwide and actively engages in the development and manufacturing of components for the aerospace market, leveraging its environmental resistance capabilities.

myonic GmbH

Steinbeisstr. 4, 88299 Leutkirch, Deutschland

myonic Product Website (English &

German)

Industry

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.