What is a torque meter?

What is a torque meter? Explanation of how it works, types, and points for selection.

Torque meters are instruments that measure the "torsional force" applied to a shaft, and are used in quality control of day-to-day products, experiments and research. Yet as there are few opportunities to view torque meters in day-to-day scenarios, not many people know about the specific measurement mechanisms in detail and in what situations they are useful.

The following is an explanation of the mechanism, types and usage scenarios of torque meters, as well as key points for selecting products.

1. A torque meter is a device that measures torque

orque is the torsional force (force to rotate and force to stop) applied to a shaft, and the device to measure torque is called a torque meter. To illustrate this using a familiar object, torque is the force applied when turning a screw with a screwdriver or rotating the cap of a plastic bottle to open it.

Torque meters can measure the force as a numerical value in the direction of rotation with respect to a shaft.

For example, when rotating a shaft by applying a force of 1 N from a position 1m from the shaft, the force applied on the shaft is "1 N (force) x 1m (distance) = 1 Nm (torque)."

Torque is larger the further the force is applied from the shaft.

How torque meters work

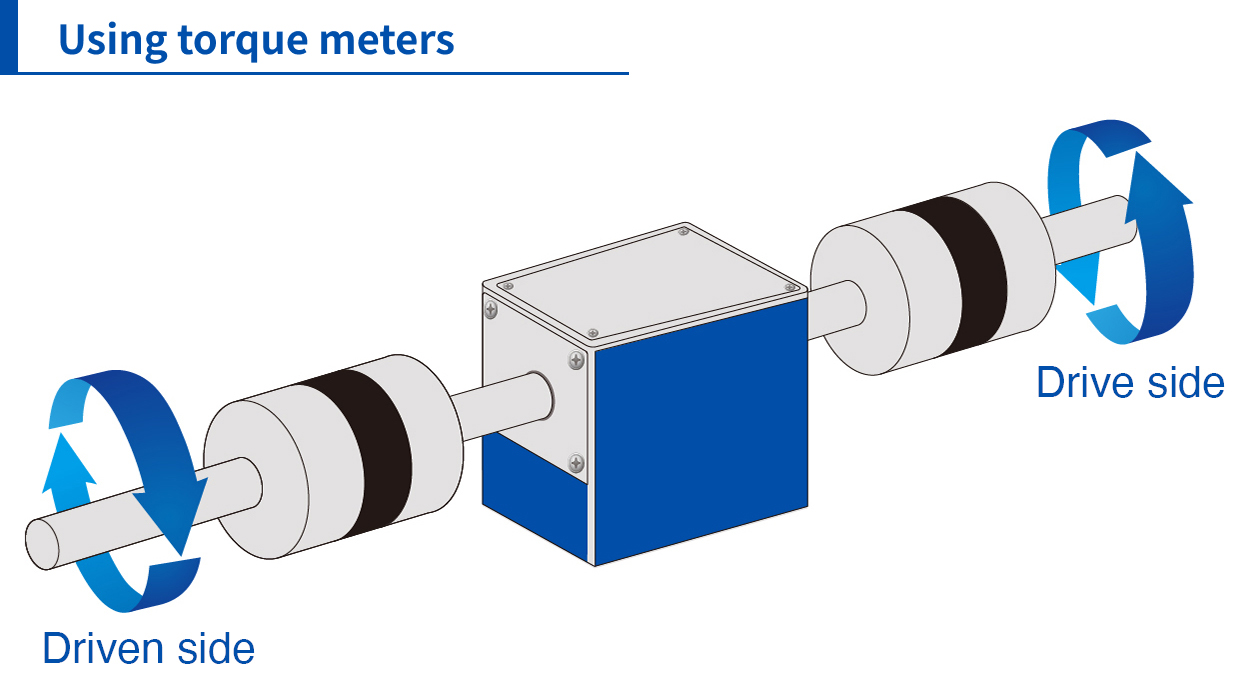

The basic mechanism of a torque meter is to measure torque—a torsional force—by connecting a torque meter between the rotating shaft on the drive side and the rotating shaft on the driven side, and rotating them.

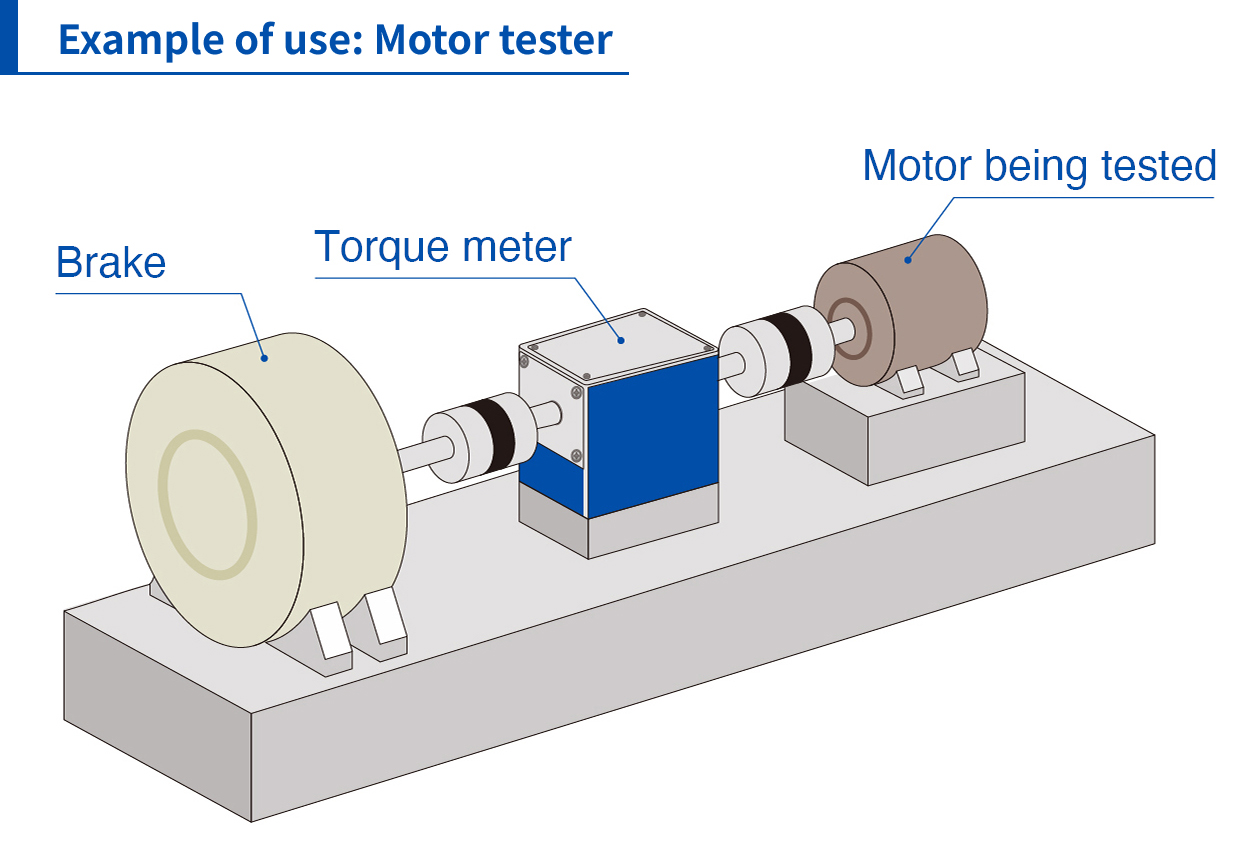

For example, rotational power transmitted by a motor or other device is installed on one side, and a mechanism using that rotation, such as a turbine, is installed on the other side, to measure the force required for rotation.

2. What are torque meters used for?

Torque meters are mainly used for quality control on production lines and for experimental and research purposes, and are useful in the manufacture and development of familiar products. Let's take a closer look at specific situations in which torque meters are used.

Appliances and household goods

An example of a torque meter in use is for checking operability and convenience, like the torque needed to rotate an audio volume knob or whether the torque to roll out lip balm is suitable for users.

Torque meters are used as measuring instruments to support quality control, like evaluating operability and conformance to industry standards.

Automobiles and motorbikes

In addition to engine performance testing of automobiles and motorbikes, torque meters are also used for testing the performance of motors in electric and hybrid vehicles.

Torque in engines and motors refers to rotational power, which affects the acceleration and hill climbing ability of automobiles and motorbikes. As the output (horsepower) of automobiles or motorbikes is calculated by "torque x rpm," torque is an important indicator when measuring the performance of an engine or motor.

Some products incorporate a torque meter in the drive shaft of automobiles to measure torque while they are in motion. In addition to providing real-time information on environmental performance such as fuel economy, the system also helps to improve safety by detecting malfunctions.

3. Types of torque meters

There are various types of torque meters, depending on the method of torque measurement and the shape of the meter. Let's go over the types of torque meters available along with their features.

Optical transmission type

Optical transmission type torque meters measure torque by converting measured strain into an electrical signal, which is then converted into an optical signal that emits an LED and is received by an optical receiving element. The advantage of this is that digital signal transmissions have lower noise.

There are two shapes of torque meter—flange type and shaft type. The flange type is thin and can be installed in a space-saving manner. The compact and lightweight design of the axial type model allows for greater flexibility, such as when it is embedded into machinery.

■Optical transmission method flange type torque meter"TMHSB"

Features a compact and lightweight design with bearing-free structure for high rotation. The split structure of the antenna part makes it easy to install and remove.

■"TMRS" (shaft type) low-capacity shaft torque meter

Has a low capacity (0.5 Nm) but allows for high-precision and high-speed rotation. It is also highly responsive for detecting sharp torque variations.

Axial type rotary transformer system

Axial type rotary transformer systems are an electromagnetic induction type torque meter with two sets of transformers, one for the power supply and the other for signal transmission. Electromagnetic induction enables non-contact signal transmission, which is beneficial for facilitating high rotation speeds and being maintenance-free.

■"TMNR" Series torque transducer

Extensive lineup ranging from low-capacity (10 Nm) to high-capacity (10 kNm) models. The non-contact signal transmission system eliminates the need for problematic brush replacement and reduces work required for maintenance.

Low-capacity slip ring method

The low-capacitance slip ring method measures torque by transmitting the signal through a slip ring (silver ring brush). It is capable of detecting minute torque.

■"TMBN" Series torque transducers for low torque

This series is suitable for detecting minute amounts of torque. They are designed to be compact and lightweight for space-saving installation.

4. Torque meter selection

When selecting a torque meter, first check the torque and rotational speed to be measured. As the permitted overload and maximum rotation speed vary depending on the type, select the appropriate product for the torque to be measured.

Care should also be taken regarding the position of the torque meter. To measure torque correctly, it is important to ensure the torque meter is installed so that the shafts connected to its left and right sides are aligned, so check that there is sufficient space for the torque meter.

Also, check that the temperature of the operating environment is within the allowable range of the torque meter.

5. What is required for torque measurement?

Torque measurement requires a device that receives signals from a torque meter and displays them as numerical values. The device connects to the torque meter to digitally display measured values as well as output signals. The output signal is used to control and monitor the measurement system.

■"OPT-564" special transmitter for optical transmission torque transducer

Special transmitter for optical transmission type torque meters. Receives signals from torque meters and displays torque and RPM digitally.

6. If you need a torque meter, contact MinebeaMitsumi an inquire about our extensive product lineup.

Products that use torque—the torsional force—are all around us, and torque meters are used in a variety of situations, including product quality control and research and development. Expertise is required for deploying torque meters, as the appropriate product depends on the purpose of torque measurement.

MinebeaMitsumi's product lineup includes flange and shaft type torque meters that transmit signals optically, as well as shaft type rotary transformer type torque meters, making it possible to construct torque measurement and torque measurement systems that meet any required objective.

The new "TMRS" low-capacity shaft torque meter is a low-capacity (0.5 Nm), high-accuracy, and high-speed rotation type in a compact and lightweight design. MinebeaMitsumi offers advice and suggestions catering to the needs of customers, from the latest and most diverse range of torque meters. If you are seeking to deploy torque meters, do not hesitate to send us an inquiry.

For product-related inquiries, please contact us using the form below.

Related page

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.