What is a tensile and compression testing machine?

What is a tensile and compression testing machine?

Explanation of Electromechanical Universal Testing Machine principle and structure

A tensile and compression testing machine is a device that can perform both tensile and compression strength tests with a single unit. Tensile and compression testing machines are used in a wide range of industries and situations because they can measure and test the strength of materials and products.

Some examples of where they are used include in academic environments such as universities and various research institutes, as well as in technology research and development departments such as corporate R&D centers, for the following types of applications.

<Main applications of tensile and compression testing machines>

- Development of new materials and products

- Analysis of defects and accidents

- Testing materials and establishing test methods

- Performance evaluation of products

They are also often used by manufacturing and quality assurance departments of manufacturers for various quality inspections and quality assurance.

1. Tensile and compression testing machines are devices for testing the physical properties of objects

As the name suggests, a tensile and compression testing machine is a device that performs various tests by applying tensile or compressive force to an object (material or product). Given that a single unit is capable of performing multiple tests, it is also called a universal testing machine.

Tests can be used for materials and components such as metals, rubbers, textiles, plastics, and construction, as well as actual products. Physical characteristics (physical properties) such as stress, strength, modulus of elasticity, and elongation, and mechanical properties can be quantified and tested.

Tensile and compression testing machines can be replaced with specialized jigs to perform various tests such as bending, shear, peeling, and friction tests, in addition to tensile and compression tests.

There are various types of tensile and compression testing machines, but the current testing machines in use can be broadly classified into two types: hydraulic tensile and compression testing machines and electromechanical tensile and compression testing machines. MinebeaMitsumi manufactures and sells electromechanical type machines.

Electromechanical tensile and compression testing machines use load cells, a type of force sensor, to detect forces.

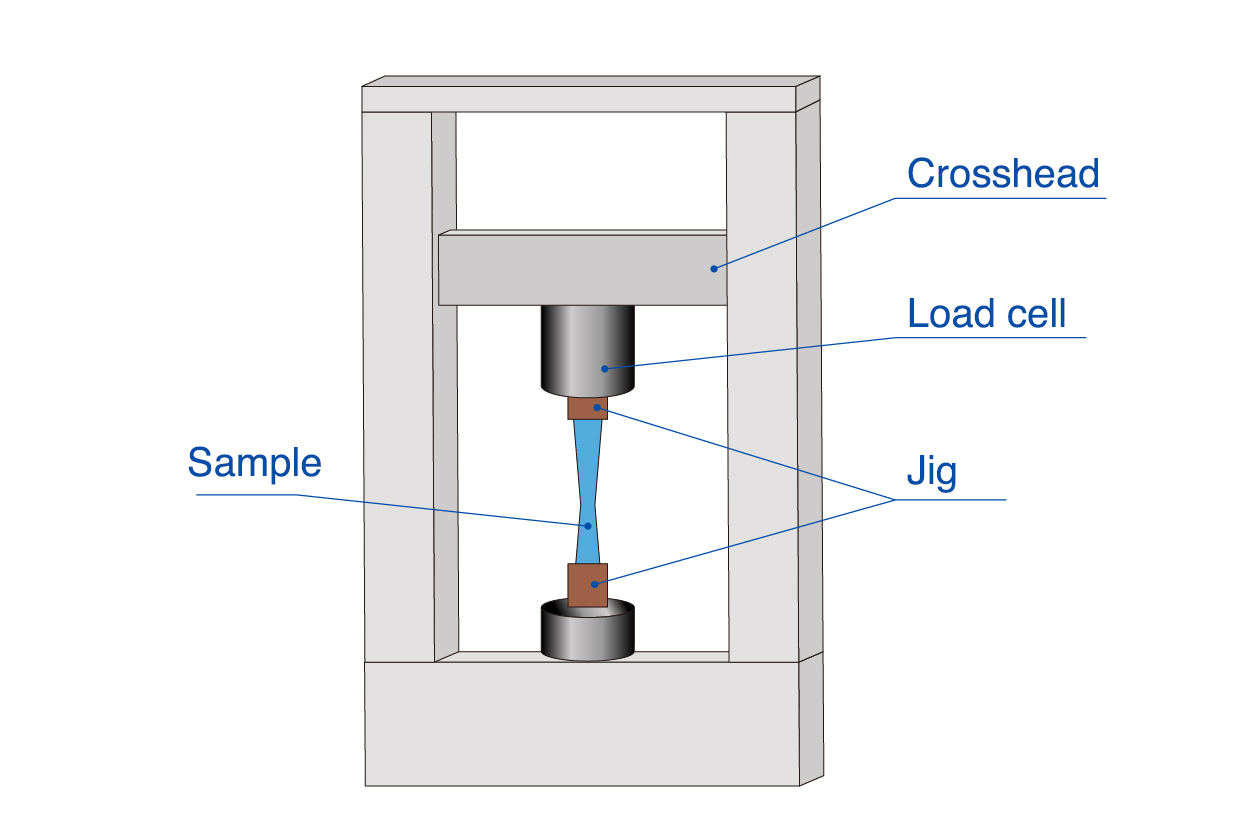

Basic configuration of electromechanical tensile and compression testing machines

Electromechanical tensile and compression testing machines generally consist of a jig suited to the object (material or product) and a load cell to measure the force.

2. Purpose of tensile tests and measurement methods

The purpose of tensile tests and measurement methods are first outlined here.

Purpose of tensile tests

Tensile tests are generally performed to test the performance and quality of materials that are expected to be used under tension. Quality can be assured by quantifying the longevity, safety and durability of materials, parts and products.

For example, mechanical properties such as Young's modulus (modulus of longitudinal elasticity) and breaking elongation are important factors for improving product functionality and assuring safety, and can be quantified using tensile and compression testing machines.

Some unique applications of tensile testing include evaluating the strength of biological tissues such as bone, muscle and skin, as well as medical devices such as artificial joints, artificial heart valves and drains (various types of tubing).

Tensile test measurement methods

引Tensile tests are primarily performed on materials such as metals, rubbers, fibers, and plastics. Often conducted as part of material tests to check the mechanical properties of materials, these are one of the most important tests for performance and quality inspections.

The specific procedure for tensile tests is to first shape the material being tested into a defined geometry. Next, the material is attached to the tensile and compression testing machine with a jig called a chuck (grip), and pulled up in the vertical direction.

3. Purpose of compression tests and measurement methods

The purpose of compression tests and measurement methods are now outlined here.

Purpose of compression tests

Tensile tests are generally performed to test the performance and quality of materials that are expected to be subjected to weight.

These are used by research institutes and manufacturers to examine the mechanical properties of materials under compression, or to test the degree to which objects are subjected to compression to determine whether they will fracture or lose performance.

The strength and durability of each and every cardboard box, container, concrete and metal members used in construction, and other items can be quantified using tensile and compression testing machines.

Compression test measurement methods

As outlined above, compression tests are sometimes performed on materials for tensile and compression testing, but they are also performed on products.

The specific procedure for compression testing begins with the attachment of a jig called a pressure plate/pressure-resistant plate to the tensile and compression testing machine. Next, the target material or product is placed and compressed from above and below.

4. If you need a tensile and compression testing machine, contact MinebeaMitsumi and inquire about our extensive product lineup.

Various tests are required for new materials, developing materials, and for further improving and refining products. The results of the tensile and compression testing machine measurements ensure the safety and security of the products we use and live with every day.

MinebeaMitsumi offers a wide range of electromechanical tensile and compression testing machines, from tabletop size to large models suited to a variety of applications. We also supply data processing software that can be used in combination with our tensile and compression testing machines.

For product-related inquiries, please contact us using the form below.

Related page

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.