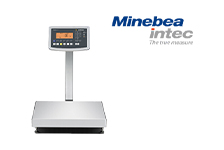

In addition to being used to measure the elasticity, proof stress and strength of materials, such as metals and plastics, these machines also help evaluate the quality of assembling in destructive tests and manufacturing processes of products.

< Multifunctional, Easy-to-Use Tensile and Compression Testing Machines >

Featuring indicators and switches integrated on their front operation panel, the machines have an easy-to-use design. The also make test control from a PC, data analyzing and data summarization possible, through using data processing software.

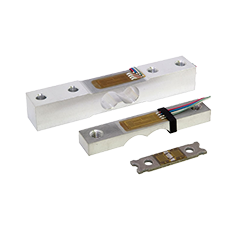

Use of High-Precision Load Cells and Control Systems Made in-house.

Using know-how in high-precision load cells and instrument digital indicator made in-house, Minebea produces feature-rich, easy-to-use systems with a better safety device.

Features

・Strength testing with simple operation

・For tensile/compression/bending testing

Bag opening force, bond strength, peel strength, adhesive strength, film tensile strength, press-fit and riveted component extraction force measurement, material and product bending

strength measurement.

Uses an encoder to measure displacement, and measures displacement with a resolution of 0.01mm.

・Revolutionary design

Prominent digital display, easy-to-use key placement, and space for samples and jigs.

・Full range of convenient functions and safety devices

force auto zero function, test force display range selection (×1 to ×10), load cell registration, sample rupture detection function, interface function (USB 2.0/1.1 compliant), overload prevention function, load cell, data acquisition software, interface cable provided as standard.

-

-

scroll

Specification name

Specification contents

Maximum test force 50 N / 200 N / 500 N / 1 kN Movable crosshead stroke 20~ 310 mm [20 ~ 460 mm] between the chucks

(when the optional chuck PCH-500N-012 is applied.)Movable crosshead speed range ・Standard test speed

・ S500 : 50, 100, 200, 300, 400, 500 mm/min

・ S400 : 40, 75, 100, 200, 300, 400 mm/min

・ S300 : 30, 50, 100, 150, 200, 300 mm/min

・ S200 : 15, 20, 50, 100, 150, 200 mm/min

・ S100 : 10, 20, 30, 50, 75, 100 mm/min

・ S50 : 5, 10, 20, 30, 40, 50 mm/min

・ S20 : 1.5, 2, 5, 10, 15, 20 mm/minReturn speed Test speed or RAPID RETURN (maximum speed selection), with zero-overshoot function Speed Accuracy Speed setting ±3% (with no load) Displacement measurement resolution 0.01 mm Test force display Range 1: ー50.00 to 50.00/-200.0 to 200.0/ー500.0 to 500.0/ー1 000.0 to 1 000.0

Range 10: ー5.000 to 5.000/-20.00 to 20.00/ー50.00 to 50.00/100.00 to 100.00

5-digit digital displayMeasurement range selectable from [x1] and [x10] Measurement accuracy Relative reading error ±1.0% (equivalent to JIS B 7721 Class 1) Peak detection function Test force value and position value at the peak is displayed after completing the test by select mode. Auto zero Automatic zero is adjusted by [ZERO] key. Analog output -5 VDC to +5 VDC (output connector: BNC female) Safety device Overstroke preven -tionlimit switch

Stops movable crosshead movement during operation.

Upper/lower limits for movable crosshead movement rangecan be set as desired.Emergency stop switch Shuts off all power when operated. Overload prevention function Stops movable crosshead when test force reaches 102% of the load cell rated capacity Interface function (USB connector port) USB2.0 compliant; can also be used with USB1.1 standard devices

(Connector B type female), communication cycles: 20 times/sPower supply voltage / frequency Single phase 100 VAC±10 VAC 50/60 Hz Power consumption Approx. 300 W External dimensions (W×H×D) (mm) 475 mm x 710 mm x 347 mm [475 mm x 860 mm x 347 mm ]

(excludes protruding parts)Weight Approx. 18 kg [19 kg] Standard accessories Load cell (select one from 50 NB, 200 N, 500 N, or 1 kN),

100 V AC power supply cable (2.4 m with 2-pin adapter),

midget fuse (5 A), USB interface cable (2 m), instruction manual (1 copy),

data acquisition software (1 CD-ROM including USB driver)Options Cable for analog output , Data processing software for tension,

compression and bending test (SR-09-001), Data processing software for peel test (SR-09-002) -

Click the arrow icon in the table below to switch from ascending to descending order.

scroll

Parts No.

CAD files[DXF]

Specification sheet

LTS-50NB LTS-200NB-500NB.zip LTS-50NB No.ENLTS4150 LTS-200NB LTS-200NB-500NB.zip LTS-50NB No.ENLTS4150 LTS-500NB LTS-200NB-500NB.zip LTS-50NB No.ENLTS4150 LTS-1kNB LTS-200NB-500NB.zip LTS-50NB No.ENLTS4150 -

Instruction Manual

Custom

- ※Custom products are intended for mass production. Please consult us for small-lot orders.

Featured Products

Engineering Information

Basic Knowledge

Download

Product Topics

Industry

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.