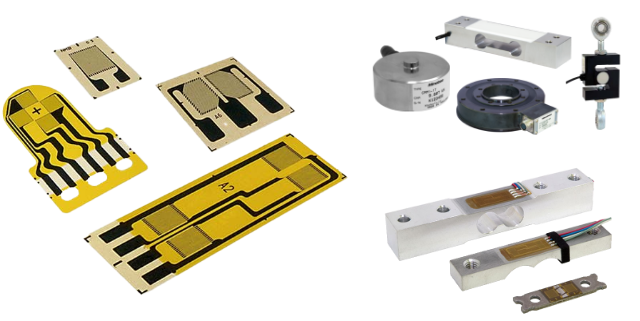

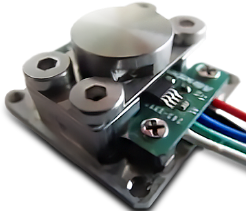

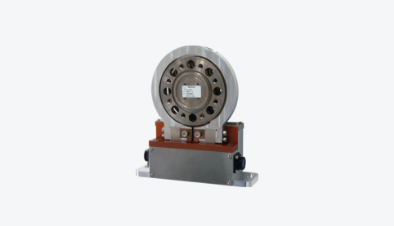

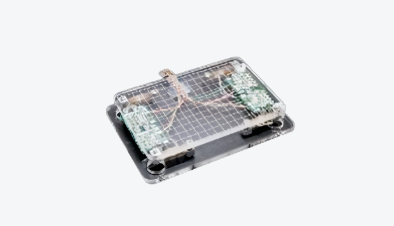

Various custom sensors

made to meet the customer's applications and requirements.

MinebeaMitsumi manufactures high-precision measurement products with applied technical capabilities

utilizing strain gages developed in-house. Supplying custom-made products tailored to the customer’s

usage environments.

Contact us for requests about customization.

- ※Custom-made products are designed for mass production. Inquire for details about small production runs.