Application

Aircraft

Helicopters

Automobiles

Railway vehicles

Ships

Rockets

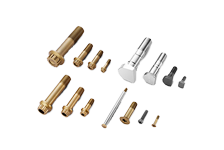

BOLTS

Overview

These are the most typical examples of fasteners used for assembling engines and fuselage panels.They are manufactured from a variety of materials in order to meet application requirements.Thus,for assemblies requiring high tensile strength and fatigue strength,high-tension (up to 260ksi) bolts are suitable;for applications involving high temperatures and corrosive conditions,nickel alloys and heat/corrosion-resistant steels are chosen;and if weight is critical,titanium alloys are employed.

NUTS

Overview

Various self-locking nuts are available-such as 6-point nuts,12-points nuts and floating nuts (one lug or two lug) .They are made of various alloys,as well as heat-resistant and corrosion-resistant steels.To prevent galling,molybdenum disulfide lubricant is used,and silver plating is applied if the nuts are to be exposed to high temperatures.

RECESS SCREWS

Overview

These bolts,which have a dovetail groove at the base of the head recess,play an important role in the high-torque fastening of fuselage exterior panels and other applications.

Industry

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.