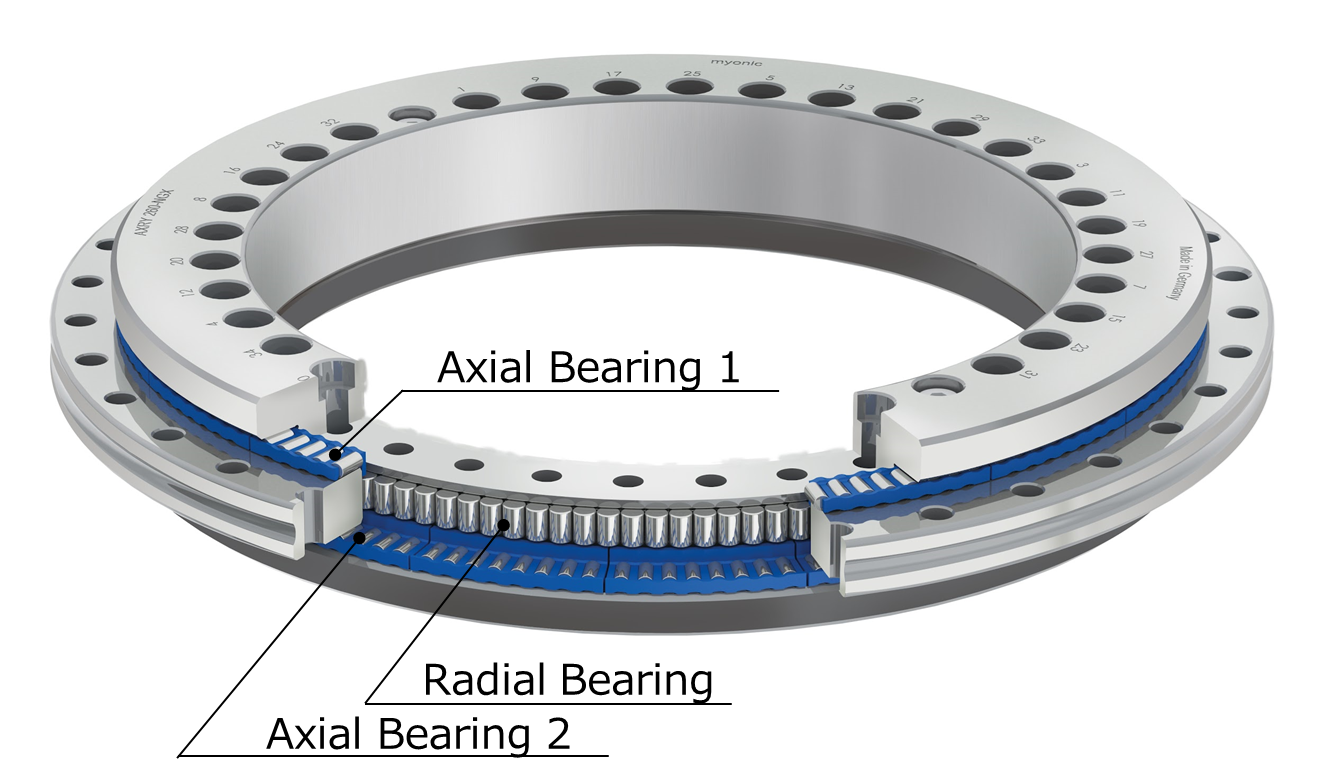

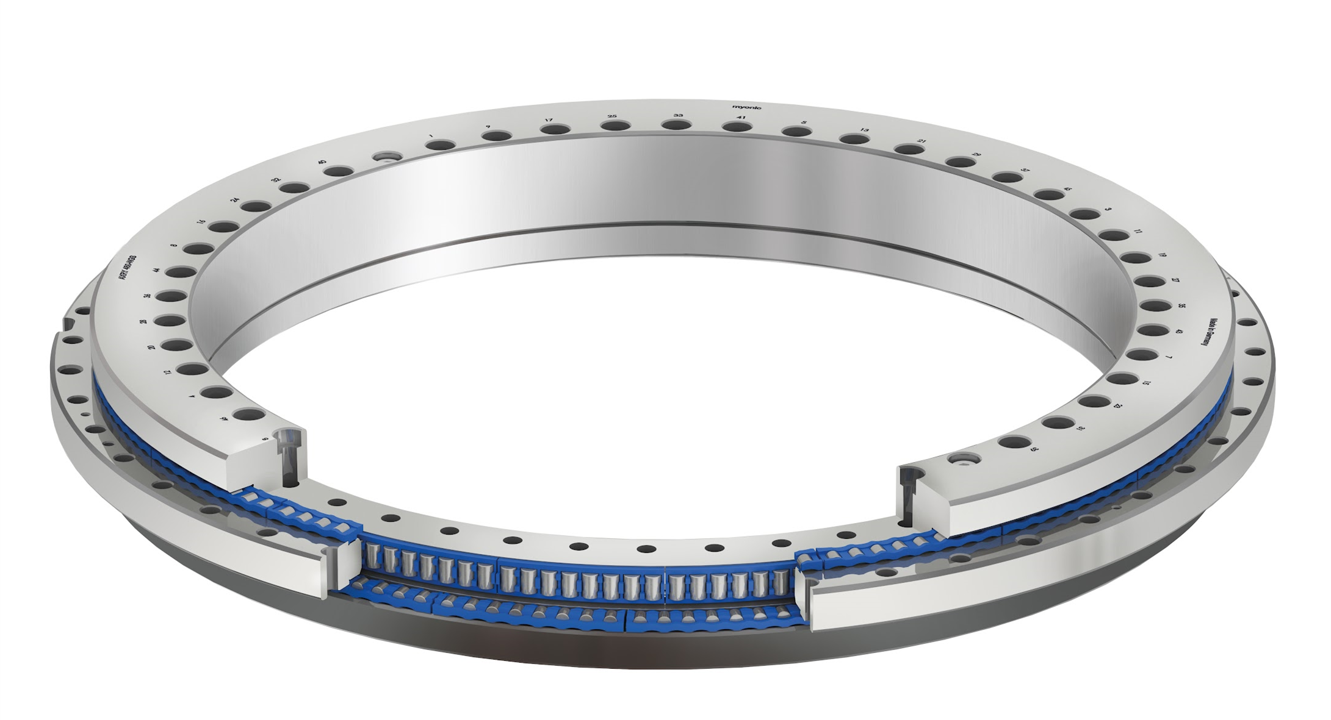

Axial Radial Bearings are precision bearing units that integrate three bearings and can be mounted on both the top and bottom surfaces, with an inner diameter ranging from 50mm to 650mm.

They are ideal for applications requiring high rigidity, such as rotary tables and milling heads in machine tools.

By absorbing axial and radial loads, as well as tilting moments, without backlash, they ensure high machining accuracy for machine tools and processing heads.

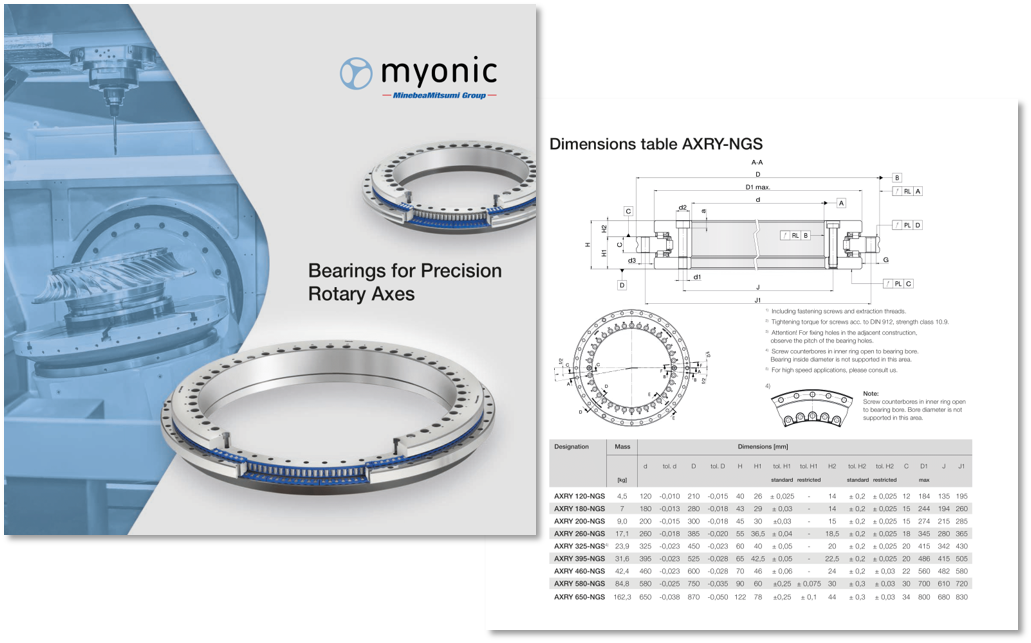

We offer two standard series: the NGX series, which optimizes rigidity with its unique design, and the NGS series,which optimizes high-speed rotation.

Lineup

High-rigidity ─NGX Series

-

Achieves up to a 25% increase in rigidity

-

Stronger rings

-

Minimizes bearing deformation

-

Compatible with outer ring rotation design (-SBI type)

High-speed rotation + High-rigidity ─NGS Series

-

Capable of high-speed and continuous rotation

-

Minimal temperature difference between inner and outer rings

-

Stable in low friction torque range

-

Compatible with outer ring rotation design (-SBI type)

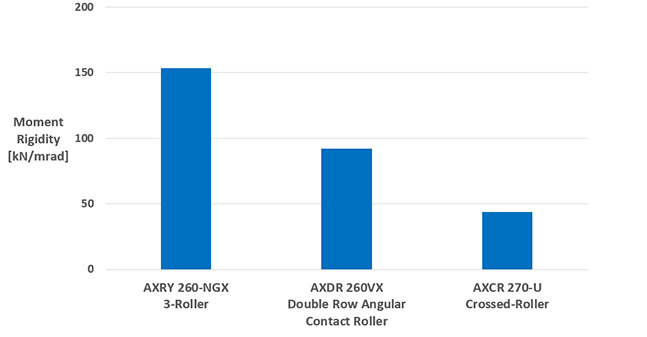

Bearing Type Rigidity Comparison (Catalog Data)

You can scroll

|

Items |

Dimensions |

Rigidity |

||

|---|---|---|---|---|

| Bearing | Inner Diameter |

Outer Diameter |

Moment | |

| Model | Type | mm | mm | kN/mrad |

| AXRY 260-NGX | 3-Roller | 260 | 385 | 153.5 |

| AXDR 260VX | Double Row Angular Contact Roller |

260 | 385 | 92.2 |

| AXCR 270-U | Crossed-Roller | 270 | 400 | 44.0 |

About myonic

myonic was established in 1936 as RMB SA and merged with MinebeaMitsumi in 2009. With manufacturing facilities in Germany and the Czech Republic, Myonic specializes in the production of ultra-small ball bearings for the high-precision dental and medical equipment markets, as well as high-rigidity bearings for machine tools, based on its advanced precision bearing manufacturing technology. Due to its high quality, myonic has gained significant trust worldwide and actively engages in the development and manufacturing of components for the aerospace market, leveraging its environmental resistance capabilities.

From development to processing and assembly, myonic responds to customer needs from the early stages of development with a highly experienced technical team and state-of-the-art equipment.

myonic GmbH

Steinbeisstr. 4, 88299 Leutkirch, Deutschland

myonic

Product Website (English & German)

Industry

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.