What is a load cell?

What is a load cell? Explanation of how it works, types, and points for selection

A load cell is a sensor that detects a force or mass and converts it into an electrical signal. They are used in a variety of fields, from scales and weighing instruments in day-to-day life to performance testing of presses and engines in industrial applications, helping to improve product quality and productivity. Yet few people know much about load cells in any detail because they are rarely visible in person.

The following is an explanation of the mechanism and usage scenarios of load cells, as well as key points for selecting types and products.

1. Load cell is a sensor that detects force or mass

A load cell is a sensor that detects force or mass (tension, pressure, torsional force, etc.) and is also called a load transducer. Force or mass is converted into an electrical signal and output, and the electrical signal is amplified and given a numerical value by an instrumentation device connected to the load cell.

As force and mass values digitized by load cells can be stored as data, they are used for product inspection, data aggregation and other purposes throughout the industry.

For example, by measuring the mass of a product, it can be used to detect defective units that do not meet the specified weight. Measuring force and mass and recording them as data also helps to improve product quality and productivity, and reduce costs.

Load cells are used in a variety of fields because they are relatively inexpensive and have a longer service life than other sensors.

2. Load cell mechanism

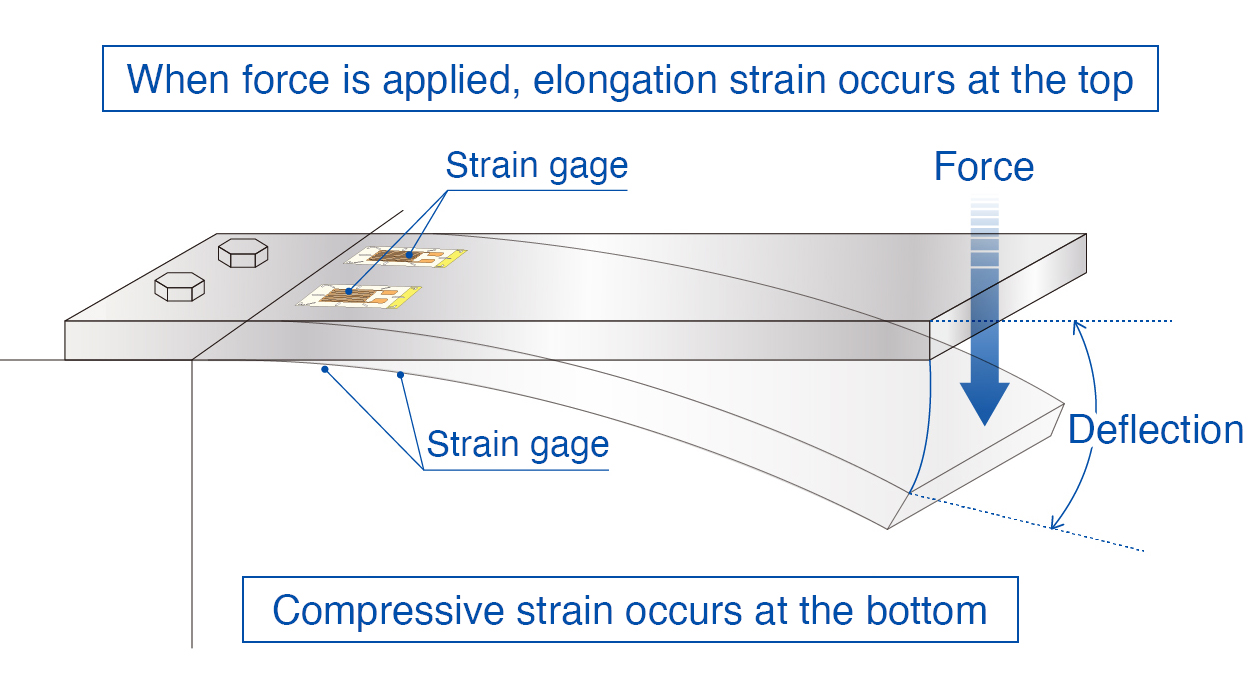

A load cell has components that deform in proportion to the applied force or mass, and to which strain gages are attached. A strain gage is a component that can measure the ratio of the amount of change (strain) before and after deformation by changing the electrical resistance value corresponding to the amount of deformation.

When a load cell is deformed by a force or mass, the attached strain gage is also deformed at the same time. The change in electrical resistance of the strain gage due to deformation is converted into an electrical signal by the load cell, thereby giving the force and mass a numerical value.

The deformation of the load cell when a force or mass is actually applied is such a small change that it is not visible with the naked eye.

Related page

What is a strain gage? Explanation of how it works, how to use it, and points for selection3. What are load cells used for?

Load cells are used in a variety of situations where force and mass are measured, from familiar products such as digital scales and weighing instruments to performance testing in engine development. Let's take a closer look at an example of a load cell in use.

Management of medical equipment

Load cells are also used in the medical field. A typical example is the management of medical equipment, such as measuring the weight of the liquid in an intravenous drip bag and informing the user when it is time torefill the bag. By attaching it to the bed, it can also monitor changes in the patient's weight and sleep patterns based on how the patient tosses and turns.

Microwave ovens and other home appliances

Load cells are also used in systems that determine the cooking time for automatic heating and defrosting in microwave ovens based on the weight of the food. It is also used for controls such as with bidet toilet seats that require the user to be seated to use the bidet function.

Automobile crash tests

Load cells are often used for testing the strength of products. Examples include measuring the impact of automobile collisions or the load of seatbelts when under tension.

Other tests, such as material tensile and bending tests, are conducted to study strength and performance by measuring changes in the material.

4. Types of load cells

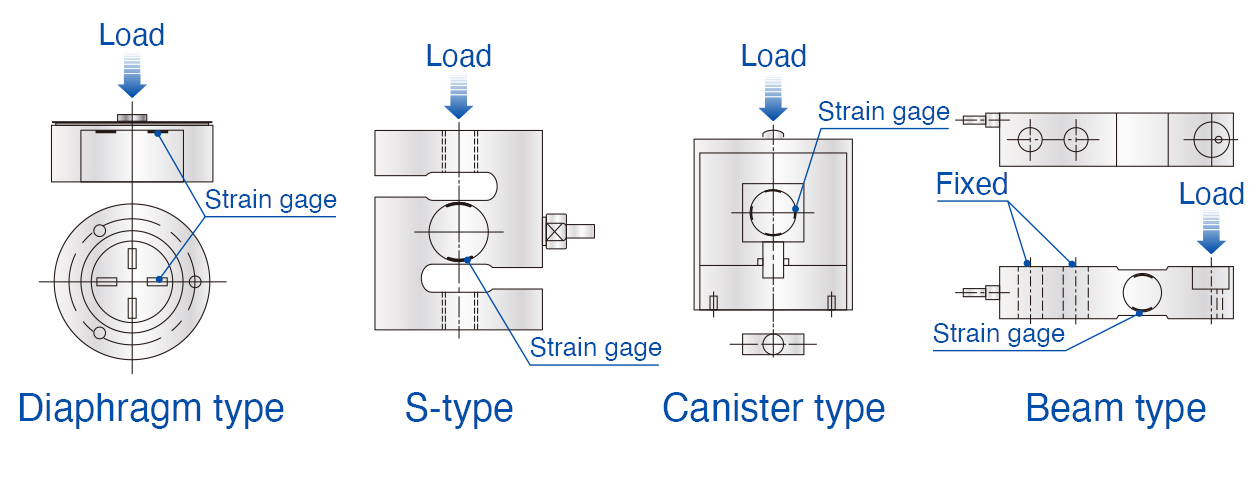

There are four main types of load cells, depending on the shape of the components that deform when a force is applied. Let's take a closer look at the characteristics of each type.

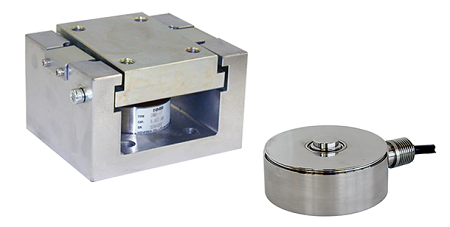

Diaphragm load cell

Diaphragm load cells are those with a circular-shaped body. A strain gage is attached to the underside of the circle and a load is applied to the center, to measure the amount of deformation. Compared to S-type and canister type load cells, this type is beneficial in that the height of the body can be reduced.

■ Accurate compression type load cell "CMP1"

Diaphragm loads cell feature all-stainless steel construction for thin precision compression. The combination of the steel ball method mounting attachment with slide stop mechanism (SCA-CMM1) increases the horizontal strength, making the specifications suitable for use under harsh conditions, such as belt conveyor scales, tanks, and hopper legs.

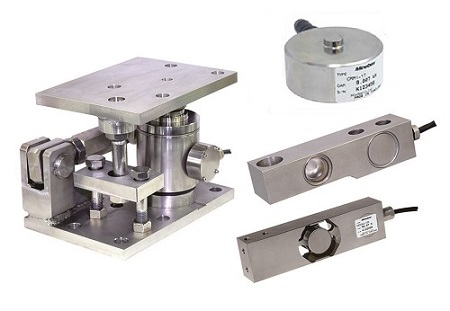

S-type load cell

S-type load cells are those with a body in the shape of a letter S. A strain gage is attached to the middle part of the S shape, and deformation can be measured by applying load to both ends of the S shape. This type is suitable for measuring compressive and tensile loads, and is often used for fatigue and tensile testing of materials.

■ S-shaped beam type load cell "U3S1" series

Suitable for tank scales/hopper scales and other various tensile weighing devices.

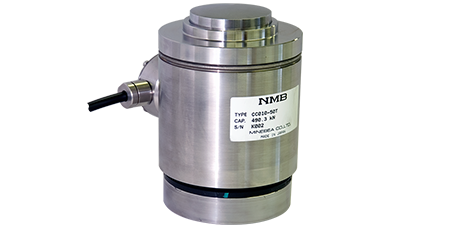

Canister type load cell

Canister type load cells are those with a body in the shape of a cylinder. A strain gage is attached to the center of the cylinder to measure the amount of deformation in the compressive direction of the cylinder surface when a load is applied from the top of the cylinder. They are suitable for measuring large loads.

■ Double convex type compression service load cell "CC010" Series

Canister type load cell with automatic centering mechanism. The all-stainless steel sealed construction provides excellent environmental resistance.

Beam type load cell

Beam type load cells are those with a main body shaped like a plate similar to a diving board. Strain gauges are attached to the top and bottom of the board to measure the amount of deformation caused when applying a load to the tip of one side of the board. Load cells are suitable for measuring bending loads and shear loads, and are also used for platform scales.

■ Square beam type load cell "C2B1B" series

A hermetically sealed, all-stainless steel beam load cell with excellent environmental resistance. Highly accurate weighing is possible through the combination of an automatic centering function.

5. Load cell peripherals

Given the very small electrical signal detected by the load cell, instruments must be connected that amplify the signal and display it as a numerical value. Digital display indicators are commonly used, and selecting one by checking the visibility of the numbers, high accuracy, and quick response time is recommended.

In addition to displaying values, some products are equipped with functions such as analog and digital data output, control and monitoring of weighing systems.

■ Graphic digital indicator "CSD-912B"

A graphic digital indicator that displays signals from load cells as weighing values. It provides various functions such as notifying weighing status via status indicator lamps, controlling weighing operations, and expanding weighing systems for measurements and instruments by connecting external devices. Up to 100 weighing objects can be registered.

■ "PR1626" intrinsically safe explosion-proof interface developed especially for load cells

An interface between the load cell and instrumentation equipment is also available to minimize changes in load cell output due to temperature effects and to enable highly accurate measurements in harsh environments. Developed especially for load cells installed in hazardous locations, up to 4 load cells can be connected to the PR1626/60 and up to 8 load cells to the PR1626/61.

6. Load cell selection

Load cells come in a variety of shapes, including diaphragm and S-types. The appropriate load cell depends on the type of force or mass to be measured, such as measuring compressive or tensile forces or mass, so the load cell that best suits the purpose of the required measurements should be selected.

When loads are being measured, attention should also be paid to the corresponding load capacity of the load cell. Select a unit with a margin greater than the rated capacity.

The environment in which the load cell will be installed should also be verified. As load cells are subject to force and mass, they cannot be installed in unstable locations. If a load cell is installed in a location where the applied force or mass causes it to sink into the ground, the correct values cannot be measured. An installation site with the sufficient strength must be available.

For environments with harsh surroundings such as large temperature fluctuations, be sure to check temperature, dustproofing, waterproofing, and other specifications.

7. If you need a load cell, contact MinebeaMitsumi an inquire about our extensive product lineup.

Load cells are used in a variety of situations, from familiar home appliances to product research and development sites, and their applications are continuing to grow due to their high level of precision and long service life. There are various types of load cells, and the appropriate model depends on the type of force or mass to be measured—expertise is required for deploying load cells.

MinebeaMitsumi load cells use strain gages with proprietary design and development for outstanding long-term stability, and an extensive lineup of load cells is available, ranging from small, low-capacity scales to high-capacity industrial load cells. MinebeaMitsumi offers advice and suggestions catering to the needs and required measurements of customers. If you are seeking to deploy load cells, don't hesitate to send us an inquiry.

For product-related inquiries, please contact us using the form below.

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.