Force Torque Sensors

Force torque sensors are sensors that measure the magnitude of force and torque in real time, and can perform high precision sensing. Demand is expected to grow for mid- to small-sized force torque sensors for small robots. Also, the adoption of MEMS is increasing in areas where it had been difficult to incorporate force torque sensors due to price and other issues.

This section describes the applications and features of force torque sensors and MinebeaMitsumi’s miniature 6-axis force torque sensors.

- What Is a Force Torque Sensor?

- Force Torque Sensors Using MEMS

- Application Examples of Force Torque Sensors

- MinebeaMitsumi’s Force Torque Sensors

What Is a Force Torque Sensor?

Force torque sensors are devices that measure the magnitude and direction of forces and torques acting on an object. Using an analogy to the human senses, these sensors give robots and other machines a precision sensing ability.

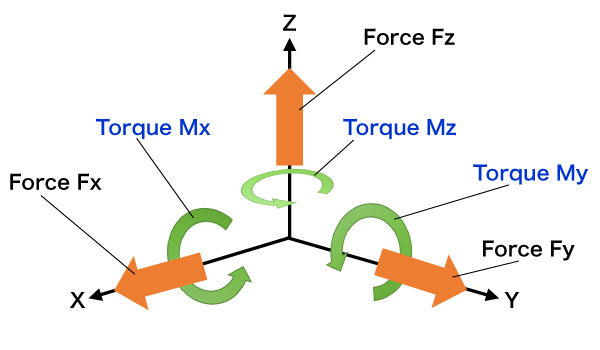

A 6-axis force torque sensor is a force torque sensor that can measure the force applied to each of the X, Y, and Z axes and the force (moment/torque) applied in the direction of rotation of the X, Y, and Z axes.

In addition to 6-axis force torque sensors, there are other types of force torque sensors such as those that measure force and torque on a single axis, 3-axis force torque sensors that detect force on three axes, or force on two axes (X and Y) and torque on one axis (Z), and various types of force torque sensors are used depending on the application.

Force Torque Sensors Using MEMS

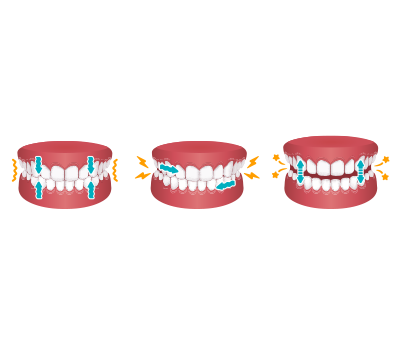

Force torque sensors using MEMS can measure forces and movements, and can also measure the balance when grasped as a force in the direction of rotation. Mounting a force torque sensor on a robot enables work operations that require human-like tactile sensations.

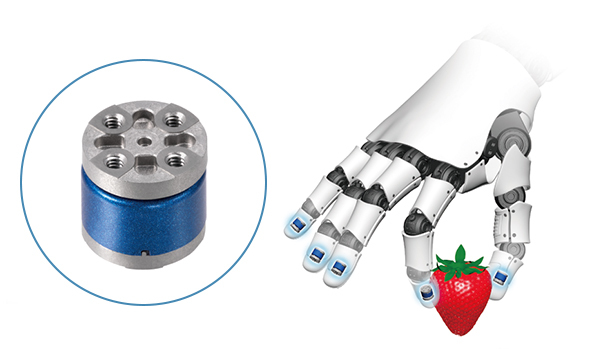

The detection methods used in force torque sensors include strain gauge, piezoelectric, optical, capacitive, and other types, and are mainly used in the wrist of robots. Miniature force torque sensors are manufactured using the MEMS process, and include magnetic, pressure, and piezoelectric elements. For example, a miniature force sensor may be used to detect the force applied to the fingers of a robot hand.

Application Examples of Force Torque Sensors

This section presents application examples of 6-axis force torque sensors.

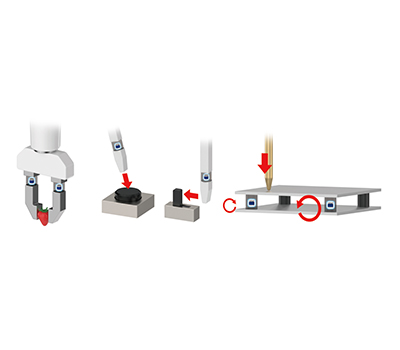

Typically, 6-axis force torque sensors are mounted to the wrist of a manufacturing robot arm, and their main applications include deburring and polishing. Conventional robot arms can only perform predetermined movements, but a robot arm equipped with a 6-axis force torque sensor can freely and easily determine the work movement, enabling finer movements than before.

In addition to robots, the 6-axis force torque sensors are also used to collect data in wind tunnel experiments for measuring the lifting force of blades.

MinebeaMitsumi’s Force Torque Sensors

Articulated industrial robots are often used in the automotive manufacturing process. Consequently, the robots have been large, and the measurement range for the 6-axis force torque sensors used has generally been relatively large at around 100 kg.

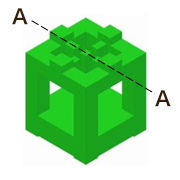

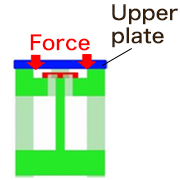

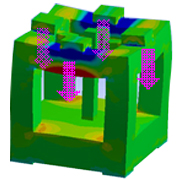

However, as the number of robots deployed in the electronics and service fields increases and robots with a rated range of less than 20 kg become more widespread, the applications for force torque sensors are also expanding. MinebeaMitsumi’s miniature 6-axis force torque sensors using MEMS have achieved a compact size and high ratings through a unique configuration of MEMS and an elastic body, and are used in a wide range of industries and fields.

by the elastic body

Features

By utilizing MEMS technology, MinebeaMitsumi’s miniature 6-axis force torque sensors are among the world’s smallest and lightest class*, measuring ⌀9.6 × 9 mm, and can be used in narrow spaces where sensors could not be used before.

Also, because they are digital (SPI) 6-axis force torque sensors, they are more resistant to noise than analog sensors and can acquire more accurate data. Since the sensor is manufactured using a semiconductor process, it is easy to mass-produce. The combined sensor of MEMS + elastic body, manufactured using our proprietary technology, features both a compact size and high ratings.

Based on MinebeaMitsumi’s research.

Product Descriptions

| Item | Specifications |

|---|---|

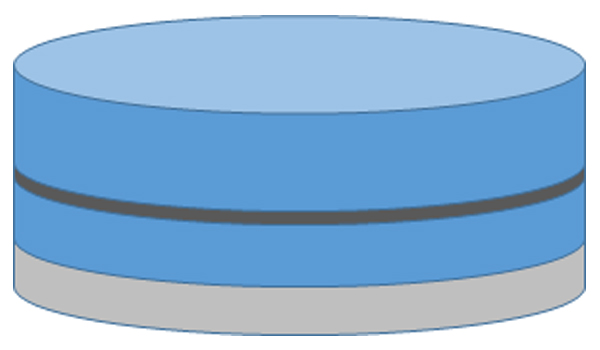

| Size (outer diameter × height) | ⌀9.6 mm × 9.0 mm |

| Weight | 3.0 g |

| Rated load (force, moment) | 40 N, 0.4 N·m |

| Load capacity (force, moment) | 200 N, 1.8 N·m |

| Theoretical resolution (force, moment) | 0.001 N, 0.00001 N·m |

| Effective resolution (RMS noise) Fx,Fy/Fz | 0.04 N/0.06 N |

| Effective resolution (RMS noise) Mx,My/Mz | 0.0004 N·m/0.0008 N·m |

| Linearity | ±1.0% FS |

| Hysteresis | ±1.0% FS |

| Accuracy | ±5.0% FS |

| Interface | SPI |

| Conversion time | 0.78 msec |

| Supply voltage | VDD 3.8 to 14 V VDDIO 1.14 to 3.6 V |

Usage Example

Examples of usage include robot hands, dental and medical devices, and drones.

These sensors are also used in autonomously controlled robot hands at leading manufacturers in Japan. In addition to the sensor’s push sensation and vibration detection, its compact size and light weight make it suitable for use in a wide range of fields.