Structure of MEMS

MEMS refers to components in which electronic circuits and mechanical elements, such as sensors and actuators, are built into a 3D structure on a silicon wafer or other substrate.

This section presents the structure of MEMS and its component elements.

Main Structure of MEMS

MEMS is manufactured in a 3D structure, in which an actuator that performs mechanical operations and a sensor that outputs electrical signals from a force applied to an element are formed on a semiconductor substrate. By integrating components that were previously incorporated as separate parts into a chip as micrometer-order components, machines can be made smaller and more integrated, and products can be made smaller and lighter.

Since devices and components can be made with higher performance and greater functionality, this technology is being used in a wide variety of applications such as accelerometers, gyroscopes, and pressure sensors as a technology that will bring innovation to industry.

Main Elements Comprising MEMS

Sensors

MEMS sensors convert various physical phenomena in the natural world, such as pressure, magnetism, electrostatics, and heat, into electrical signals.

For example, in the case of an accelerometer that utilizes the piezoresistive effect, in which resistance changes depending on deformation, the piezoresistive element formed in the weight’s indicator deforms when the weight where acceleration is applied moves. By reading and calculating this change in resistance, the acceleration can be measured.

For pressure sensors and force torque sensors, the elements in the MEMS also deform due to various movements. The sensor acts by converting the changes in resistance, capacitance, and other parameters during this process into electrical signals.

Actuators

The word “actuator” originally meant “something that makes something move,” and is a device that converts energy into some form of motion. Until now, actuators were mainly used in large devices. However, with the advent of MEMS, miniaturization is now possible, and further applications are expected.

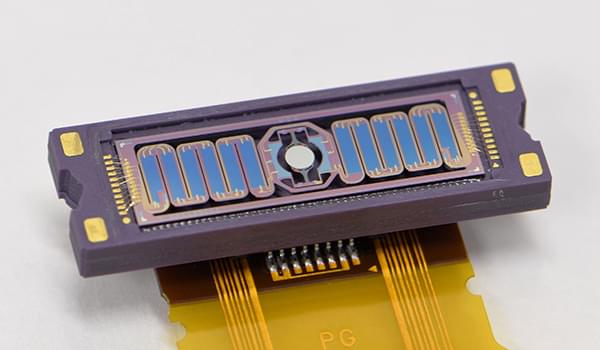

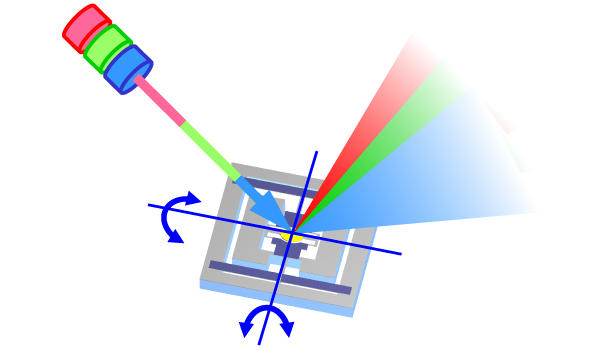

For example, the MEMS mirror developed by MinebeaMitsumi uses a piezoelectric element that deforms when voltage is applied as a MEMS actuator, and the mirror can be moved vertically and horizontally by the movement of the piezoelectric element and the control circuitry. This enables the laser beam to be reflected by the mirror surface for scanning.

The use of a piezoelectric thin film also has the advantage of being compact and power-saving, and of integrating high-speed operation with low-speed operation by non-resonant driving.

Electronic Circuits

For example, for sensors, the electronic circuits in MEMS amplify and correct the output of MEMS elements, or convert analog signals to digital signals and make them easier to process by processors such as micro controller units (MCUs) and microcontrollers.

In addition to those that process raw data for correction, some MCUs have recently been equipped with “edge AI functions” that allow the terminal itself to make various decisions.

Other Elements

Other MEMS incorporate elements that emit heat, electrodes that generate electricity, and quartz crystals, and more, and these various elements interact with each other to enable complex processing.

Furthermore, MEMS that incorporate peripheral functions of various devices and have higher functionality are also emerging, and these high-functionality MEMS devices enable products themselves to be more advanced, smaller, lighter, and more energy-efficient.