Flow Sensors

Flow sensors are used to accurately measure the velocity and flow rate of gases. The types of flow sensors include flow rate sensors and flow velocity sensors, as well as airflow sensors that can sense air speed and direction. This section presents the features of MinebeaMitsumi’s flow sensors.

- What Is a Flow Sensor?

- Flow Sensors Using MEMS

- Application Examples of Flow Sensors

- MinebeaMitsumi’s Flow Sensors

What Is a Flow Sensor?

A flow sensor is a sensor that detects the velocity or flow rate of a liquid, gas, or other substance. There are two types of detection methods: contact and non-contact. The contact type measures directly, so the principle is simple and enables high-accuracy measurement, but requires a predetermined design or construction in existing facilities when installed. The non-contact type, on the other hand, does not directly touch the object, so the error may be larger depending on the measurement method, but installation is simple and measurement can be easily started at existing facilities.

Flow Sensors Using MEMS

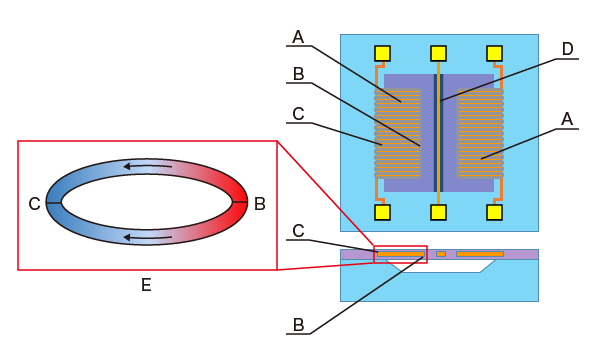

- A: Thermopile

- B: Warm contact

- C: Cold contact

- D: Heater

- E: Seebeck effect (converting temperature difference into voltage)

Flow sensors using MEMS make use of the Seebeck effect, in which the heat transmitted to a thermocouple (thermopile) generates an electromotive force. The flow of gas changes the heat distribution from the heater, causing a difference in the heat transmitted upstream and downstream, which generates an electromotive force.

Temperature correction and linear correction are applied to this generated electromotive force before output as the flow rate.

Application Examples of Flow Sensors

Flow sensors are used to measure the flow rate and flow velocity of gases. For instance, in household fuel cell systems (air and gas flow measurement) and ventilators, these sensors have the role of detecting the air flow and air velocity in these devices to control and regulate gas flow.

MinebeaMitsumi’s Flow Sensors

MinebeaMitsumi’s flow sensors convert temperature differences into voltage through the Seebeck effect*. The voltage then undergoes A/D conversion using a delta-sigma (ΔΣ) analog-to-digital (AD) converter connected to a digital signal processing device such as a microcontroller to measure flow rate and velocity.

The Seebeck effect is a phenomenon in which a potential difference is generated when the two ends of two different metal wires are connected to form a loop and a temperature difference is applied to the connected area.

Features

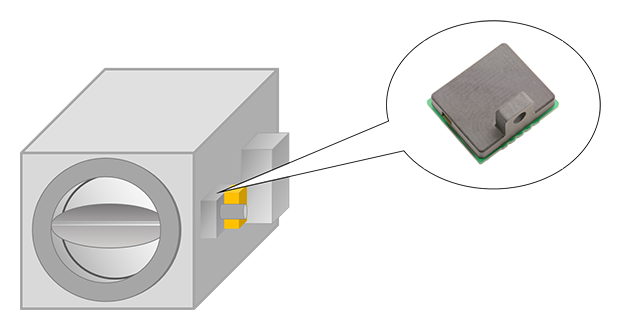

MinebeaMitsumi’s flow sensors feature a compact size and digital output. The compact size allows for greater freedom of installation in customer product design, and the digital output enables fast response, high accuracy, and high resolution. There are three types of flow sensors: a sensor that measures the pressure difference between upstream and downstream, a sensor that measures flow rate, and a sensor that measures air velocity. The flow sensor, which measures air speed, is suitable for air speed measurement applications up to 10 m/s.

Also, in the airflow sensor, a heater placed on a MEMS chip uses a sensor to measure the temperature distribution created by the air speed and direction, and like the flow sensor, uses a delta-sigma AD converter to perform A/D conversion on the voltage for output.

MinebeaMitsumi’s flow rate sensor outputs digital values using an on-board 24-bit resolution delta-sigma AD converter, and features a response time of 5 msec or less. I2C is used for the interface to communicate with the microcontroller.

The breeze sensor also uses I2C as its interface to measure the direction and velocity of air and gas media.

I2C is a synchronous serial communication interface that uses serial data (SDA) and serial clock (SCL) signals to communicate with clearly differentiated roles for master and slave devices. The master generates the SCL signal, which in turn controls the signals.

Product Descriptions

| MMS501 | MMS601 | MMS651 | |

|---|---|---|---|

|

|

|

|

| Applicable media | Air, natural gas | Air | Air |

| Measurement range | −250 L/min to 250 L/min * Customizable |

−500 Pa to 500 Pa/0 Pa to +250 Pa/−50 Pa to 50 Pa | 0 m/s to 10 m/s * Customizable |

| Zero point accuracy | - | ±0.2 Pa | - |

| Span accuracy | - | ±3% RD | - |

| Accuracy | ±5% RD (10% to 25% FS) ±3% RD (25% to 100% FS) |

- | ±5% RD (1 m/s ≤ flow velocity ≤ 10 m/s) |

| Supply voltage range | 2.7 V to 3.6 V | 2.7 V to 3.6 V | 2.7 V to 3.6 V |

| Response time (msec) | - | < 5 | - |

| Temperature characteristics | - | 0.5%RD/10°C | - |

| Operating temperature range (°C) | −20 to 80 | −20 to 80 | −10 to 60 |

| Resolution | 24-bit | 24-bit | 16-bit |

| Interface (output format) | I2C | I2C | I2C |

| Size (mm) | 73.0 × 24.0 × 38.0 | 26.0 × 18.0 × 24.0 | 20.0 × 17.0 × 13.0 |

Usage Example

This sensor is expected to be utilized in a wide range of locations such as in variable air volume (VAV) controllers, household gas pressure sensing, and medical ventilators.