MEMS Applications in the Air Conditioning Equipment Industry

Due to recent climate change and changes in society, there is an ever-increasing need to improve energy efficiency and reduce the environmental impact of air conditioning equipment. MEMS sensors are used in air conditioning systems ranging from home air conditioners to air conditioning systems in buildings and factories, and are expected to both help solve these social issues and contribute to the creation of a comfortable environment.

- Types and Roles of MEMS Sensors Used in Air Conditioning Equipment

- MinebeaMitsumi’s MEMS Devices Utilized in the Air Conditioning Equipment Industry

Types and Roles of MEMS Sensors Used in Air Conditioning Equipment

The MEMS sensors used in air conditioning equipment include flow sensors that detect air volume and air direction, absolute pressure sensors that measure atmospheric pressure, and temperature and humidity sensors that detect temperature and humidity. For example, recent air conditioners are equipped with IR sensors, and MEMS devices also contribute to higher energy efficiency, for example, by detecting people in the room to activate the air conditioning without wasting energy.

MEMS Sensors for Controlling Air Conditioning Systems

Heating, ventilation, and air conditioning (HVAC) is a system that controls the temperature, humidity, and air chambers inside a building or vehicle. Many MEMS sensors are used in this HVAC system. For example, in the air conditioning system of a building, air volume is measured by air volume detection sensors installed in each room and adjusted to send the appropriate air volume to each.

MEMS sensors are also used to detect air pressure, temperature, and humidity, and to detect leaks of new refrigerant gases, making MEMS sensors an indispensable part of air conditioning systems.

MEMS Sensors Utilized in VAV/CAV

Variable air volume (VAV) and constant air volume (CAV) are both systems that adjust the air volume in air ducts according to a preset value using sensors or other devices. Both are devices that adjust air volume, automatically adjusting it to the desired air volume and then controlling it to maintain that air volume at a constant level.

MEMS flow sensors are used in these VAV and CAV devices to help control heating and cooling capacity. These sensors measure the speed of air flowing through the air conditioning ducts and adjust the volume of air blown by opening and closing the damper blades according to the indoor load (temperature difference).

Also, the trend toward mandatory installation of ventilation equipment is spreading, especially in Europe and the United States, and the use of MEMS flow sensors is expected to increase in the future for enabling greater visualization of ventilation.

MinebeaMitsumi’s MEMS Devices Utilized in the Air Conditioning Equipment Industry

MinebeaMitsumi’s MEMS devices are also used in air conditioning equipment. Our MEMS devices, such as our breeze sensors and IR sensors, are used to control air volume and air direction and to maintain a constant indoor environment.

Breeze Sensors for Controlling Air Flow

In addition to building air conditioning management, there is a growing trend toward energy conservation through efficient management and control of air conditioning systems in “smart house” initiatives that connect homes to the Internet.

MinebeaMitsumi’s breeze sensor can measure wind direction and air velocity from 0 to 3 m/sec, making it possible to visualize even the slightest breeze flow. Also, the breeze sensor can be used not as a stand-alone device, but in combination with other modules to provide more advanced measurements.

For example, the sensor can be used in systems to improve the efficiency of agriculture, to monitor plant growth states, and in the construction industry to investigate whether air is flowing as simulated.

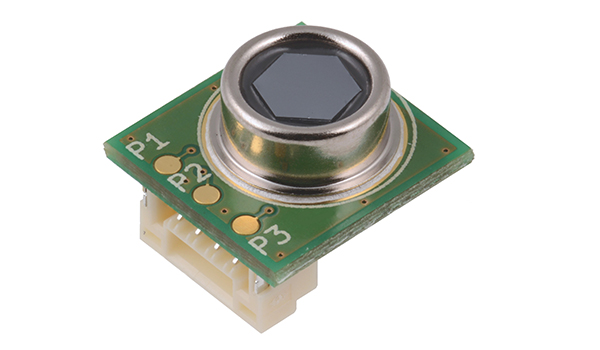

IR Sensors for Detecting People and Saving Energy

Recently, to better conserve energy, it is not uncommon for air conditioning equipment to be equipped with automatic operation functions, such as switching to active mode when a person approaches and to energy-saving mode when no people are present.

IR sensors have the capability to detect people using infrared rays and play an important role as an indispensable sensor in the automatic operation of air conditioning equipment.

MinebeaMitsumi’s IR sensors have an industry-leading* low-noise performance with a noise equivalent temperature difference (NETD) of 0.06°C or less, and can accurately measure temperatures to prevent false human detection, thus contributing to energy savings in air conditioning equipment.

According to MinebeaMitsumi research, as of January 2023.