MEMS Technology Supporting Energy Saving

Manufacturers are interested in improving energy efficiency in order to conserve power and reduce our reliance on natural resources. In recent years, energy saving efforts have intensified with global warming countermeasures, such as greenhouse gas reductions, and decarbonization. Concerns about energy security and instability in our current geopolitical environment has also contributed to urgency surrounding energy initiatives. In this article, we will focus on electric power usage, which continues to increase even amidst the ongoing calls for energy conservation, and discuss efficiency requirements and the critical role of MEMS technology in achieving significant reductions in energy usage.

- Energy Saving Changes with the Times

- What It Takes to Save Energy on HVAC Equipment

- The Future of Energy Saving and MEMS

Energy Saving Changes with the Times

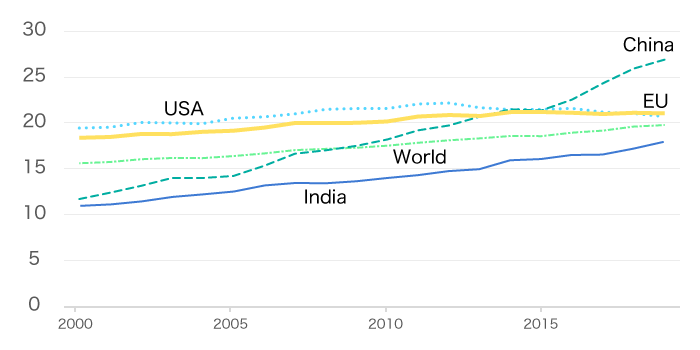

The demand for global energy continues to increase, both for primary energy (as raw material), and for final energy (what users actually consume). The share of electricity usage, which is expected to increase as global decarbonization progresses, continues to grow worldwide. China and India in particular, which are experiencing remarkable economic growth, are showing rapid increases in their power usage.

(2000–2020)

In recent years, the increase in electricity usage by air conditioning and other HVAC equipment due to global warming has also become an issue.

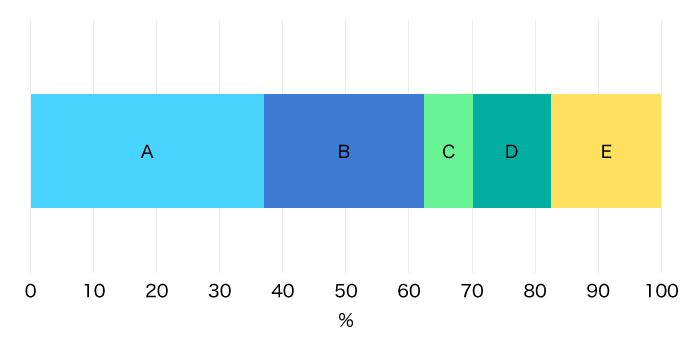

According to the IEA (International Energy Agency), the electricity demand for space cooling by air conditioners is expected to triple by 2050, accounting for 37% of the total increase in electricity demand. The widespread use of air conditioners will not only increase electricity usage, but also greenhouse gas emissions. HVAC equipment is required to meet energy efficiency and greenhouse gas emission requirements, thus the importance of promoting these capabilities will be even more critical.

- A: Space cooling 37%

- B: Residential appliances 25.5%

- C: Lighting 7.8%

- D: Heating 12.4%

- E: Other services 17.4%

Source: IEA, Share of global electricity demand growth to 2050, IEA, Paris IEA. License: CC BY 4.0

What It Takes to Save Energy on HVAC Equipment

To optimize energy savings on heating, ventilation, and air conditioning (HVAC) equipment, it is important to precisely monitor and manage usage. In addition to reducing energy consumption, it is necessary to develop and adopt new technologies, such as the use of environmentally friendly materials such as lower GWP refrigerants. The following section presents the latest sensing technologies that can be incorporated into HVAC equipment to improve energy efficiency.

Sensing Technologies Support Reduced Energy Usage

A typical technology used for energy saving is an inverter. Installation of inverters enables lower energy losses, prevents malfunctions and stoppages, and ensures a stable output supply. Inverters are used in a wide variety of home appliances, but the use of inverters in room air conditioners is high. It is estimated that about 80% of air conditioners in widespread use today are equipped with inverters.

Sensing technology has been attracting attention as a means to further improve the energy efficiency of air conditioners. Today, infrared sensors are used to detect the presence of people in an area in order to provide targeted heating and cooling. thereby eliminating energy waste. Additionally, infrared arrays can be used to scan and generate a thermal map of an area to enableinteractive operation of an air-conditioning unit or heater.

Other HVAC equipment include heat exchange ventilators that use gas sensors to detect CO2 concentration in a space and automatically control ventilation, and air purifiers that use peripheral sensors to monitor isolated locations and optimize operational efficiency. The majority of HVAC equipment that performs air and heat transfer utilizes filters to protect against dust and other contaminants. This type of equipment can benefit from sensors to monitor efficiency. The sensors in these devices utilize MEMS technology, and it is forecast that MEMS sensors will continue to be an important piece in achieving energy savings.

As an example, today’s residential energy recovery ventilator keeps the air fresh in a house without losing the energy to the outside. As stale, indoor air is expelled to the outside by the ventilator, it flows across a heat exchanger where the majority of the heat is transferred prior to the exit. Simultaneously, the ventilator pulls fresh air in from the outside that intersects with the same heat exchanger and absorbs the transferred energy. Contaminants adhering to the filter and the heat exchanger impact the ventilator efficiency and drive up energy costs. MEMS sensors are ideal for this application where a pressure sensor can be used to monitor the filter condition as well as provide temperature feedback.

New Technologies and MEMS Sensors

Air conditioners and other HVAC equipment use energy-efficient heat pump technology. Heat pumps use refrigerants for cooling and heating by drawing heat from the air, and CFC gas is used as the medium.

Currently, there are two types of CFC gases used as refrigerants in the world: HCFCs (hydrochlorofluorocarbons/specified CFCs)*1 and HFCs (hydrofluorocarbons/alternative CFCs)*2. While the use of refrigerants allows efficient heat transfer, CFC gases have a high environmental impact thus regulations are being implemented as new refrigerants are being developed at. One such new refrigerant is R32. Although R32 is a type of HFC, it has an ozone depletion potential of 0 and a global warming potential of 675, one-third that of conventional refrigerants. As a result, it is in stable demand as a well-balanced CFC gas among the refrigerants currently available. However, R32 is flammable thus proper safeguards are required. MEMS sensors can be utilized to effectively detect R32 leaks and enhance the reliability of air conditioners and air conditioning systems that use refrigerants.

- The Montreal Protocol required the phasing out of HCFCs among developed countries by 2020.

- The Montreal Protocol mandated the reduction of HFCs among developed countries beginning in 2019.

The Future of Energy Saving and MEMS

Energy saving is now a global environmental issue. All member countries of the United Nations have signed and participated in the United Nations Framework Convention on Climate Change (UNFCCC), adopted in 1992, and each country is working on various measures.

Energy-saving efforts in housing and construction are progressing especially in developed countries, and energy-saving standards have been established for facilities that perform heating, cooling, ventilation, hot water supply, and lighting. The standard applies to new and renovated housing in the participating countries. Emerging countries are also taking various energy-saving measures. In January 2022, China announced its 14th Five-Year Plan, which includes major targets for energy saving and carbon emission reduction, as well as 10 priority projects. India has been working on energy saving from an early stage, with the enactment of the Energy Conservation Act in 2001 and the implementation of an energy saving labeling system for household electrical products in May 2006.

As described above, efforts to achieve decarbonization and energy saving are steadily expanding despite differing regional policies.

One of the reasons MEMS technology is attracting attention for energy saving is due to miniaturization. This feature allows more functionality within the same footprint as well as minimal power consumption.

Thus, further use of MEMS technology is expected to help solve the difficult problem of energy saving.