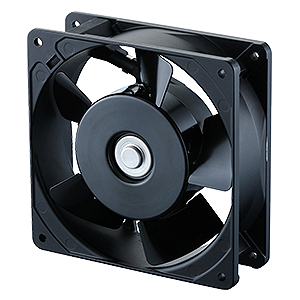

Fan Motors

Product List

Engineering Information

Technical Data

- Product Quality and Environmental Protection

- Selection of the Fan

- Measurements & Conversions

- Part Numbering System [AC fan motors / DC fan motors]

- Example of Fan compliant with IP

- Fan Life & Reliability

- Acoustic Noise

- MinebeaMitsumi High-pressure blowers Characteristics

- Outline of 60DCF

- Outline of 70DCF

- Characteristic Curves (Representative Characteristic)

- Common Specifications - DC fan motors

- Common Specifications - AC fan motors

- DC Fan Sensors

- DC Fans Speed Control

Precautions of Use

Industry

Download

Latest News

-

Fan motors that are rated at higher ingress protection levels (dust and waterproof performance) have enhanced environmental resistance

-

cTUVus certification (UL standard compliant) of High-pressure blower 60DCF&70DCF

-

Waterproof and dustproof lineup added to large DC blower fan motor!

-

New Product

Expanded DC fan motors line up!

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.