In addition to being used to measure the elasticity, proof stress and strength of materials, such as metals and plastics, these machines also help evaluate the quality of assembling in destructive tests and manufacturing processes of products.

< Multifunctional, Easy-to-Use Tensile and Compression Testing Machines >

Featuring indicators and switches integrated on their front operation panel, the machines have an easy-to-use design. The also make test control from a PC, data analyzing and data summarization possible, through using data processing software.

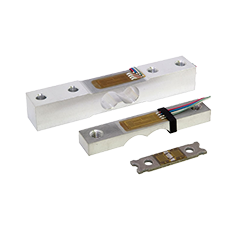

Use of High-Precision Load Cells and Control Systems Made in-house.

Using know-how in high-precision load cells and instrument digital indicator made in-house, Minebea produces feature-rich, easy-to-use systems with a better safety device.

Features

New Desk-Top testing mashine with high accuracy, high performance, and simple operation.

・High-accuracy

Accuracy of ±1 % (JIS Class 1) of the indicated value from 1/1 to 1/500 of load cell capacity; accuracy of ±0.5 % (JIS Class 0.5) is available as an option.

・High performance and simple operation

Automatic load cell span adjustment, One-push auto zero, Auto return to test start position (No overshooting), Test condition registration, Manual 3 level speed setting (freely settable), Analog output of test force and position, and support for continuous repeated tensile and compression testing.

・Light weight and compact

50 kg lighter and 100 mm slimmer than previous model (Compared with TG-10kN)

-

-

scroll

Specification name

Specification contents

Maximum test force 250 kN, 100 kN, 50 kN, 10 kN, 5 kN, 1 kN, 500 N, 200 N Test space Tensile and Compression testing beneath the movable crosshead.

(An optional model is available allowing tensile testing above the movable crosshead.)Loading method Constant-speed strain loading with high-accuracy AC servo motor and backlash-free precision ball screw Crosshead speed/permissible test force Within the max. test force over the entire speed range. Test force range Choice of ×1 (AUTO) and ×100 if load cell rated output is 3 mV/V; ×1 (AUTO) if load cell rated capacity is 20 N or less.

When ×1 (AUTO) is set: test force increase/decrease, full scale display, and automatic switching of decimal point position and display unitsTest force measuring accuracy ±1% of indicated value in range 1/1 to 1/500 of load cell capacity for both tensile and compression (A high-accuracy model with ±0.5% of indicated value is available as an option.) Applicable standard JIS B 7721 Class 1 or Class 0.5 and ISO7500-1 Class 1 or Class 0.5 Crosshead speed accuracy ±0.5% of speed setting or ±0.0025 mm/min, whichever is larger Speed setting method Manual: Numeric input via control panel (0.1, 0.5, 1 to 500 set in 1 mm/min increments)

When using data processing software: Automatically set in accordance with test conditions created.Manual speed 3 speeds (HIGH/MIDDLE/LOW); each speed freely settable Test mode Single and cycle (combination of test force and position) Optional: Creep, stress relaxation, automatic loading Display 5-digit digital display ±99,999, able to display peak or rupture test force, position: 5 1/2 digital display ±1999,999 Standard functions Load Cell model and capacity: Auto adjust

Load Cell span: Auto set for tension/compression.

Load Cell Zero point: One push

Position reset: One push

Sample rupture detection: Selectable from stop, reverse and ignore

Rupture sensitivity: Set as desired to 0.04 % to 99.00 % of test force

Test condition registration function: 10 conditions

Test force & position analog output: 0 VDC to 5 VDC (with scaling function)

Interface: Conforms to USB 2.0/1.1 standard (B-type connector)Options Chuck adapter: Lower chuck mounting adapter for tensile testing

Load Cell: for tensile/compression type (with universal joint, connecting pin, and compression plate)

for tensile type (with universal joint and connecting pin)

for compression type (with compression plate)

Test jig: Former jig is attachable.

Displacement measuring function: Strain input type

Test machine stand:

Data processing software: Single, Cycle, ControlPower supply voltage, Frequency TGE-250kN~TGE-10kN:3-phase 200 ACV±20 V, 50/60 Hz

TGE-5kN~TGE-200N: Single phase 100 VAC ~ 115 VAC, 50/60 HzOperating temperature /humidity range Temperature 5 ℃ ~ 40 ℃, Humidity 20 % ~ 80 %RH (Non condensing) Notes Note 1: The test force measurement range varies depending on the rated capacity of the load cell used.

Note 2: Testing machines are available with large effective width for models with maximum test force of 50 kN, 100 kN or 250 kN.

Note 3: Models are available with extended stroke.

Note 4: Tensile testing stroke is for maximum test force capacity load cell with the (optional) chuck mounted. -

Click the arrow icon in the table below to switch from ascending to descending order.

scroll

Parts No.

CAD files[DXF]

Specification sheet

TGE-250kN TGE-100kN TGE-50kN TGE-50kN No.ENTGE4105 TGE-10kN tge10kn.dxf TGE-10kN No.ENTGE4103 TGE-5kN tge5kn.dxf TGE-10kN No.ENTGE4103 TGE-1kN tge1kn.dxf TGE-10kN No.ENTGE4103 TGE-500N tge500n.dxf TGE-10kN No.ENTGE4103 TGE-200N tge200n.dxf TGE-10kN No.ENTGE4103

Custom

- ※Custom products are intended for mass production. Please consult us for small-lot orders.

Featured Products

Engineering Information

Basic Knowledge

Download

Product Topics

Industry

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.