Data processing software TgAnest TgAnest logo

In addition to being used to measure the elasticity, proof stress and strength of materials, such as metals and plastics, these machines also help evaluate the quality of assembling in destructive tests and manufacturing processes of products.

< Multifunctional, Easy-to-Use Tensile and Compression Testing Machines >

Featuring indicators and switches integrated on their front operation panel, the machines have an easy-to-use design. The also make test control from a PC, data analyzing and data summarization possible, through using data processing software.

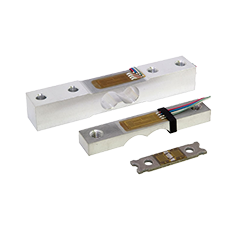

Use of High-Precision Load Cells and Control Systems Made in-house.

Using know-how in high-precision load cells and instrument digital indicator made in-house, Minebea produces feature-rich, easy-to-use systems with a better safety device.

Features

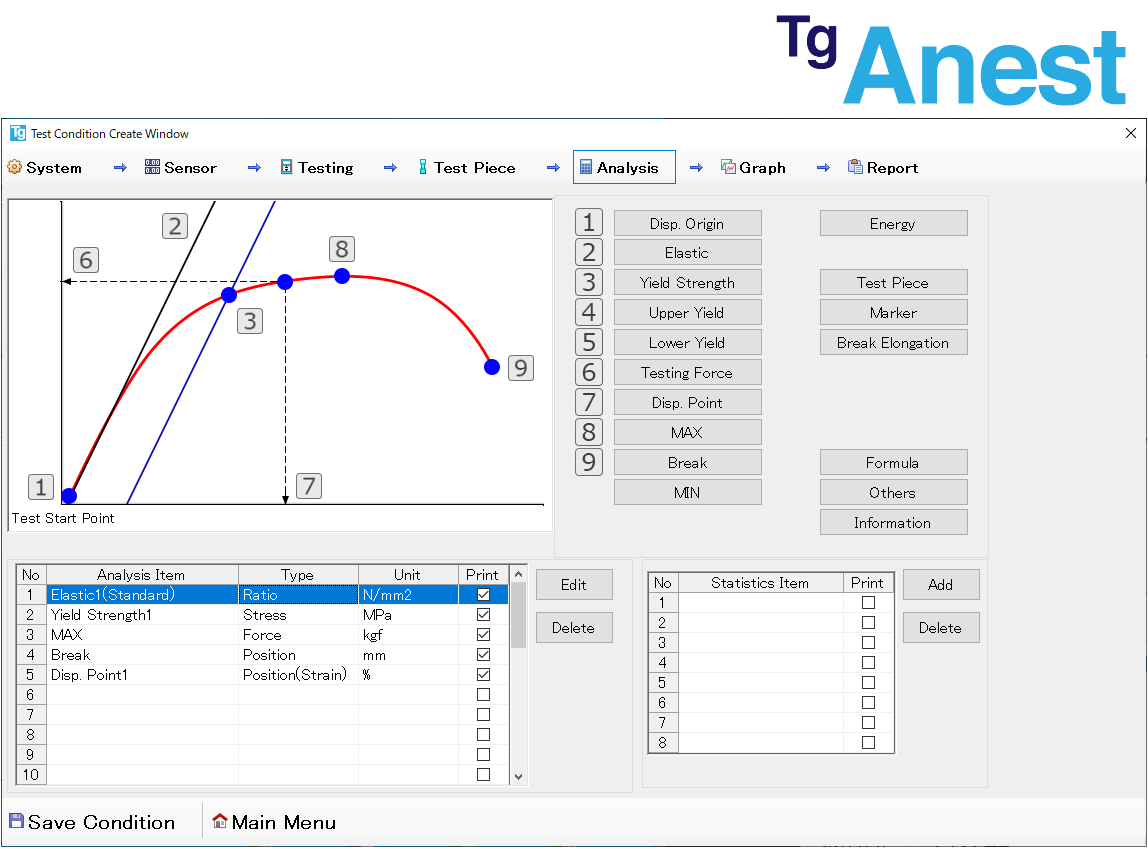

・Makes creating test conditions even easier

Intuitive setting using graphical display and improved visibility with large-size text.

The test sample dimension input also supports manual input, Excel importing, and electronic

micrometer input.

・Quick start function (30 conditions)

Registering frequently used test conditions allows you to move to the test start screen withjust one click.

The display can be switched between Japanese and English.

・Improved report creation function

Allows titles, test conditions, test samples, graphs (2 types), results, comments, andphotographs to be pasted in any location with any size to create reports.

・Sampling rate and test speed can be switched in up to four stages duringtesting in standard sampling mode.

Sampling rate: Can be set between 10 ms and 10 hours in 10 ms intervals.

Displacement: Can be set between 0.001 mm and 1,000.000 mm in 0.001 mm intervals

・With high-speed sampling (optional), this can be switched in up to

three stages during testing.

High-speed sampling of 1 ms, 5 ms, 10 ms, 50 ms, 100 ms or 150 ms can be set in up to three stages.

・Additional tests and results can be reordered.

・Supports tensile, compression, 3-point/4-point bending, and peeling in asingle package.

Control conditions can also be created by the user for creep testing,relaxation testing, and automatic load testing.

・The test of tension, compression, 3 points/4 points bend and peel are totalized in the package. Moreover, the control condition of creep test, relaxation test and automatic load test can be created for yourself.

-

-

scroll

Specification name

Specification contents

System requirements Compatible operating Windows10、Windows11

(*Windows is the registered trade mark in the United States and other nations of Microsoft Corporation)CPU Intel Pentium (Dual core or Single core) Clock speed 2 GHz or more Memory Windows10:2GB or more、Windows11:8GB or more Input device CD/DVD drive x 1 unit Outptu device USB port (for the standard sampling spec.), Serial port ( for the high speed sampling spec.) Specifications Testing types Tensile, compression, 3-/4-point bending, peeling Test modes Single (tensile, compression, 3-/4-point bending, peeling,deflection compensation)

Cycle (tensile, compression, 3-/4-point bending) (Optional)

Control (tensile, compression, 3-/4-point bending,deflection compensation) (Optional)Max test capacity 100 batches, 100 sub-batches (max. 10,000 tests per file)

* Cycle testing fixed at 1 batch, 1 sub-batch.Sampling interval Standard 10 ms to 10 h, High-speed 1 ms to 150 ms Analysis items Tensile test, compression test Displacement Origin, Elastic Modulus 1 to 3 points(Standard, Chord, Max. slope,Target),

The Maximum Point, The Minimum Point,Break Point, Upper Yield Point, Lower Yield Point, Yield Strength Point,

Intermediate Point (10 points each for test force and displacement), Energy, Initial Tension Resistance,

n value, Break Elongation,Butt Elongation, Reduction of Area, Poisson's RatioPeeling test Displacement Origin, 1st Peak Point, 1st Bottom Point, The Max. Peak Point,

The Min. Bottom Point, Tseting Forces (1 to 10 points), Average of Testing Force (2 to 10 points),

Tearing Strength, Peel Force,Integration/Simple/Peak/Bottom/Peak & Bottom/Large & Small Peak 6-Point Average,

Static/Dynamic Coefficient of Friction, Average of Collection.Cycle test Displacement Origin, Elastic Modulus(Increase/Decrease) 1 to 3(Standard, Chord, Target),

Elastic Modulus Average (Chord, Target),The Maximum Point, The Minimum Point,

Max Return Point, Min Return Point, Intermediate Point (10 points each for test force and displacement),

Midpoint Average 1 to 10,Energy (Increase/Decrease, Positive/Negative, Cycle),

Hysteresis,Hysteresis Loss, Residual Elongation.Other functions Test condition quick start, preliminary cycle,

automatic test force cancel, original point detecting function.*In addition to analysis of 'tensile, compression and three-/four-point bending tests', analysis of 'cyclic tests' can also be carried out in control mode.

-

Instruction Manual

Specification

Custom

- ※Custom products are intended for mass production. Please consult us for small-lot orders.

Featured Products

Engineering Information

Basic Knowledge

Download

Product Topics

Industry

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.