- Stepping motors

We can customize to meet your various requests!

Issue: You cannot find a product that meets all of your required specifications. You want to use a custom product.

The product specifications listed in the catalog do not match exactly! Motor size is good, but we need more torque and simple waterproofing. Is it possible to change the positions of the lead wires and connectors? The stepping motor needs to be customized to meets your required specifications, but it is uncertain what kind of response will be taken.

We can customize stepping motors according to your environment and required specifications.

We meet customer requests with customized products by providing technical consultation, creating samples, offering optional functions, and providing other services.

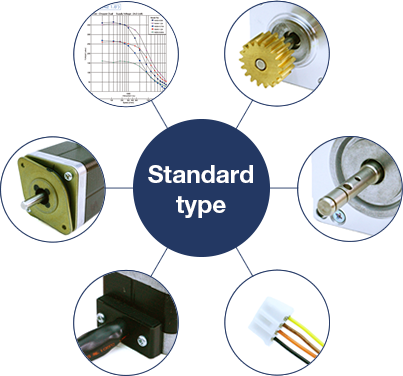

- Torque characteristic

- We design the product to

achieve the torque characteristic

that meets

your required specifications.

- Dampers

- Antivibration dampers

can be attached.

*Hybrid stepping motors only

- Simple waterproofing

and dust resistance - IP43 waterproof and

dust-resistant finish is

available.

*Hybrid stepping motors only

- Leads and Connectors

- We can process leads and connectors to the desired length and position them as specified.

- Shafts

- We can adjust the length of the shaft, and drill and cut the product before delivery.

- Gears and Pulleys

- We can deliver the product with customer-specified gears and pulleys mounted.

*Although we cannot meet all requests, please allow us to confirm the details through consultation.

Customization workflow

Our engineers and teams of specialists, such as the sales team, clarify issues and requests and mass-produce customized products.

1. Confirmation of requests: We first confirm your requests, such as the desired requirements and assumed number of lots, to determine whether we can offer customization to meet your requests.

2. Creation of samples: We create samples based on your requirements. You can check the actual samples yourself.

3. Quotation: After you evaluate the samples, we prepare a quotation that reflects any modifications and other requests.

4. Delivery of customized products: After you approve the required specifications and quotation, we prepare for mass production.

*Although we cannot meet all requests, please allow us to confirm the details through consultation.

Customization example

Customization example 1: Customization of an analyzer for medical use

We customized the shaft length, pin hole drilling, and connector attachment to achieve the best fit in the design of a medical analyzer, which must have high precision.

Application example: Medical analyzer

Assumed No. of lots: 1,000 units/month

Assumed lead time: 3 months

Customization example 2: Customization of OA equipment

We delivered OA equipment for which vibration and noise needed to be reduced by attaching an antivibration damper to the front of the motor. We also customized the gears and pulleys so that the customer does not have to attach them.

(*) Sizes that support damper attachment: □42, □56

Application example: OA equipment (e.g., printers)

Assumed No. of lots: 20,000 units/month

Assumed lead time: 3 months

Customization example 3: Customization of industrial equipment

We customized the product to achieve IP43 waterproofing and dust resistance for an industrial application in which the motor tends to be used under poor conditions. This reduced mixed power dust and other substances to better stabilize the motor.

(*) Supported sizes: □42, □56

Application example: Industrial machine

Assumed No. of lots: 500 units/month

Assumed lead time: 3 months

Related page

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.