- Power Supply IC

No amplifier or software design required. Development of an LDO for automobiles with open load/short circuit detection function.

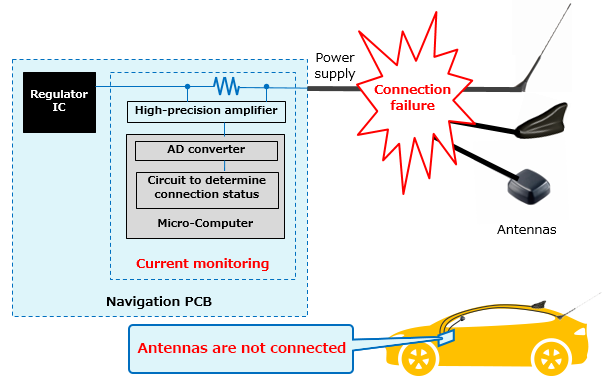

Objective: Mounting of an external device for current monitoring will increase the number of parts and losses. We want to simplify connection detection and reduce costs.

Car navigation, audio and other in-vehicle infotainment(IVI) systems require antennas, microphones and cameras. The systems used to have an external circuit measurement amplifier to detect the connection status of these external devices correctly.

In many cases, the external devices required several meters of wiring when mounted in an automobile. In addition, a circuit measurement amplifier mounted to detect open load/short circuit to increase resistance led to the loss of voltage. The need to design a system with such an inefficient configuration was a huge problem.

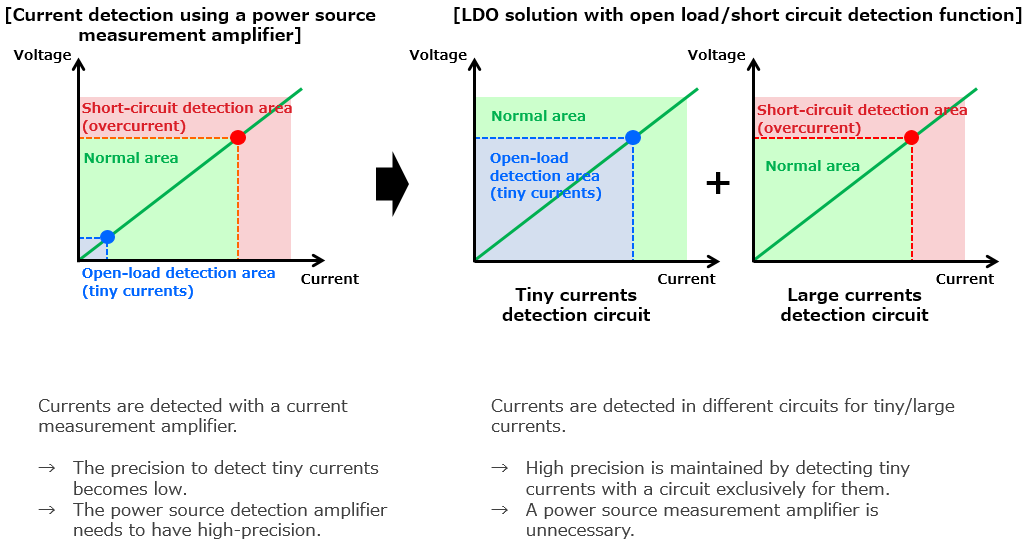

Besides, in order to detect open load/short circuit, the systems needed to detect a wide range of currents from a tiny 0.5 mA to a large 200 mA, which required a high-precision current measurement amplifier.

The more the number of parts increased, the more complicated the circuit configuration became. Furthermore, the selection of a high-precision power source measurement amplifier caused the overall costs to increase.

Is it not possible to develop an IC with a simple configuration that can accurately detect open load/short circuit while keeping the cost as low as possible? Facing the customers' problem, our semiconductor engineers changed their mindset to start prototyping a system to detect open load/short circuit without an external current measurement amplifier for current detection.

Solution: To embed a circuit to detect currents and another one to determine connection status into an IC. An all-in-one LDO with no current measurement amplifier simplifies the system.

Circuits to detect currents are divided into two and embedded into an IC.

Initially, we tried designing a system to detect currents by embedding the function of a current measurement amplifier into an IC. However, the system with a current measurement amplifier in an IC still has external resistance. There were no new elements in the configuration as resistance caused power loss.

Next, we tried measuring currents with a current mirror circuit that does not require resistance. However, it was impossible to detect both open load and short circuit while maintaining a high degree of precision because the normal detection areas of voltage and current were largely different for open load/short circuit detection.

Then we drastically shifted the design policy to divide the current mirror circuit into two for each current area for sensing.

The system maintained similar precision by detecting tiny and large currents in different circuits, which reduced current errors with no power loss caused by an additional circuit to monitor currents.

We also changed the design so that the thresholds of currents for open load/short circuit detection can be configured in an external resistor.

The circuit to determine connection status is also embedded into an IC.

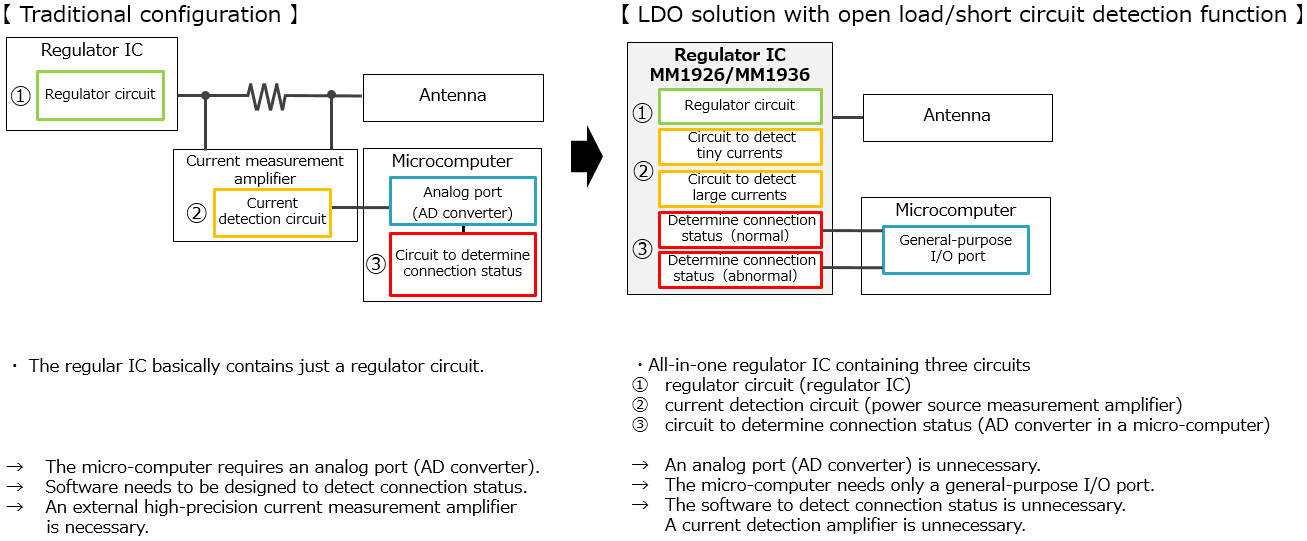

The threshold for detecting connection status used to be set using ① regulator circuit (regulator IC), ② current detection circuit (power source measurement amplifier) and ③ circuit to determine connection status (AD converter in a micro-computer).

For determining the connection status, the system required an analog port and software designed in the micro-computer.

In order to review the time and costs, we changed the design to embed the threshold circuit to determine connection status into the IC. It enabled us to develop a system without an AD converter, which had been used to detect power source in the power source measurement amplifier.

With a chip on which ① regulator circuit, ② current detection circuit and ③ circuit to determine connection status are mounted, the micro-computer requires only a general-purpose I/O port.

The simplified configuration without a high-precision current detection amplifier and AD converter in the micro-computer, which were required before, made the system much smaller and reduced the burden on the micro-computer.

Result

- Higher reliability

This is an all-in-one LDO in which [1] regulator, [2] high-precision amplifier and [3] A/D converter in a micro-computer are mounted on a chip. The simple configuration enhances reliability.

- High-precision current detection

The system can configure open load circuit and short circuit individually with an external resistor, enabling easier detection setting than before.

It can set values for open load circuit/short circuit flexibly as abnormal values according to your use conditions and purposes.

- Various external connection devices are available.

The system can detect tiny and large currents in different circuits exclusively for each circuit. It enables you to select a wider range of external connection devices.

- Space saving

The system with all this functionality is installed in a small package of 2.7 mm * 2.5 mm. The smaller package will reduce space for mounting in your application.

- Low cost

This all-in-one regulator does not require an external high-precision current measurement amplifier and an AD converter, contributing to cost reduction.

Basic information

Product or service used in this case

LDO with function to detect connection error

MM1926 seriesMM1936 series

Industrial field

Automotive related(car infotainment, TV antenna, microphone) and other external connection devices

[Standard product number]

- MM1926□□□HBE

- MM1936□□□RRE

- MM1926□□□HC2

- MM1936□□□RS2

Fields / industries where this case study can be utilized

The system is applicable to applications of which you want to know the connection status immediately as the system supplies power source to external devices with an LDO. Feel free to contact us for any inquiries.

Related page

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.