- X-ray inspection system

[Minebea Intec] Minebea Intec responded quickly to customer requirements with X-ray solution

Case Study

The X-ray inspection system (HCP Health Care Products Ltd.)

Minebea Intec responded quickly to

customer requirements with

X-ray solution Best practice

When HCP Health Care Products Ltd. needed a foreign object detection solution quickly, it was the speedy response of the Minebea Intec Sales team combined with the availability of a Dylight X-ray machine that led Minebea Intec to be its supplier of choice.

Key facts

HCP produces sweeteners in tubs which have a 90 mm diameter and are 100 mm high. They are sealed with a screw top but also have a metal foil lid. Due to the nature of the packaging, the team at HCP knew they would not be able to detect the full range of metals, including stainless steel.

Application

The X-ray inspection system needed to be placed as a critical control point. The key factors at the time were the lead times and whether the system could be commissioned on site within a very short period of time.

Customer benefits

- Rob Barker, Factory Manager at HCP states: "The most important thing about a machine like this is you can for the best part ignore it and just know it's there doing a job well. Since the machine has been in, it's not missed a beat. We have been immensely pleased with the reliability and performance."

Project goal and implementation

HCP was asked by its customer to find an X-ray solution to overcome the packaging challenge which it had at the PPMA show in 2017. Among a number of other potential suppliers, it came across Minebea Intec.

Due to the nature of its packaging containing a screw top and a metal foil lid, HCP was not able to detect the full range of metals, including stainless steel, that could be contaminating its product. This left them with two options - it could either metal detect before it finally closes the package, which still leaves it open to a risk of contamination, or it could look at using a different technology. The choice was finally made for X-ray inspection technology as a solution.

HCP asked the three potential suppliers three key questions: how well can the device detect, how quickly can you supply and at what cost?

Andrew Hallitt, an Inspection Product Specialist at Minebea Intec visited Bob Seaborne, Director of HCP at the site in Derby to discuss the application and solution. HCP had already notified HSE (Health and Safety Executive in UK) that they would be using X-ray systems soon.

Andrew quickly responded to Bob's query and invited him to the Minebea Intec showroom in Birmingham to see the available equipment in a test situation. Bob accepted the invitation and was very pleased with what he saw. The Dylight was set up on a conveyor loop with products continuously going round. Bob quickly identified that they could achieve a sensitivity performance of 1.2 mm for all metals. The test allowed over 400 products to pass through the unit without any false rejections. Test pieces were then introduced and detected.

Bob stated: "We needed the X-ray quickly. Fortunately, Minebea Intec had exactly what we needed in stock so after placing an order for just under £30,000 we had a unit in place two weeks later. When you purchase something like an X-ray for the first time, there are questions on safety specifically that you need to have answered. Andrew answered these thoroughly which put our minds at rest so we had no concerns."

The customer

HCP Health Care Products Ltd., The Sweetener Company, was established over 25 years ago and is now the largest sweetener tablet producer in the UK. The company manufactures sweetener tablets and sweetener products for large brands and supermarkets in the UK and internationally.

Support / Contact

For product-related inquiries, please contact us using the form below.

Products

The X-ray inspection system

Engineering Information

Technical information by product [Sensing Devices]

Case Studies [Minebea Intec]

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.

![[Anona] High-Speed X-ray Inspection System Addresses Foreign Object Contamination](/resource/images/sensing_devices/case-intec-x-ray-inspection-anona_thumb.jpg)

![[German paint manufacturer] High-Precision Weighing for Paint and Primer Manufacture](/resource/images/sensing_devices/case-intec-checkweighers-is_thumb.jpg)

![[pharmaceutical company in the SE Europe] Mobile Weighing for Pharma](/resource/images/sensing_devices/case-intec-digitacscale_combics3_thumb.jpg)

![[TCDRI] Reliable Detection in Harsh Environments](/resource/images/sensing_devices/case-intec-metaldetectors-secus_thumb.jpg)

![[Pharmatec GmbH] High-Precision & Hygienic Weighing Solutions for Pharma Novego](/resource/images/sensing_devices/case-intec-loadcell-novego_thumb.jpg)

![[Boehringer Ingelheim RCV] Contego® Mobile Weighing for Cleanrooms](/resource/images/sensing_devices/case-intec-loadcell-contego_thumb.jpg)

![[Ramsauer GmbH & Co KG] From Material Handling to Pre-Packaging Checks](/resource/images/sensing_devices/case-intec-digitacscale_sealant_thumb.jpg)

![[Dongyue group] Building Trust with Corrosion-Resistant Load Cells](/resource/images/sensing_devices/case-intec-loadcell-corrosion_thumb.jpg)

![[Stevin Rock] High-Speed X-ray Inspection System Addresses Foreign Object Contamination](/resource/images/sensing_devices/case-intec-truckscale_thumb.jpg)

![[BYD] High-Precision Weighing for Lithium Batteries](/resource/images/sensing_devices/case-intec-loadcell-lithium_thumb.jpg)

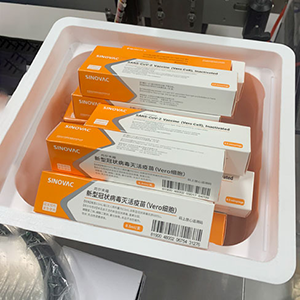

![[CanSino Biologics Inc] Supports COVID-19 Vaccine Manufacturing](/resource/images/sensing_devices/case-intec-loadcell-cansino_thumb.jpg)

![[Renowned manufacturer] Mitus® Metal Detector for Salad Dressings](/resource/images/sensing_devices/case-intec-metaldetectors-mitus_thumb.jpg)

![[Sulá GmbHh] Statistical Process Control Software Adoption](/resource/images/sensing_devices/case-intec-checkweighers-sula_thumb.jpg)

![[Valle Spluga SpA] The best sorting machine for precisely selecting poultry](/resource/images/sensing_devices/case-intec-ewk3010-thumbnail-300x300.jpg)

![[A major automotive parts manufacturer] Latest generation of metal detection coils impresses leading automotive supplier](/resource/images/sensing_devices/case-intec-vistus-rs100-thumbnail-300x300.jpg)

![[Pacific Nut Company] Vistus brings better sensitivity and space-saving metal detection solution for dried and fresh fruits](/resource/images/sensing_devices/case-intec-vistus-thumbnail.jpg)

The experience has been great. Simply put, everything we have asked for has happened from early delivery, performance and ongoing reliability. We are very pleased and will be using Minebea Intec again.

Bob Seaborne,

Director of HCP