First in Japan!*1 "Maxxis Series" for data integrity (DI) are released!

The "Process Controller Maxxis Series PR5500/PR5900" has now joined Minebea Intec's weighing system.In addition to the existing German and English, French and Japanese are also supported.

This product is a process controller used in combination with load cells and platform scales、This series, the successor to the indicator PR5510/00, is the first weighing system in Japan to comply with data integrity.

Various security functions to meet customers' DI requirements、Applicable to sensing device load cells.It can be used in combination with many other weighing solutions, such as platform scales and tank weighing systems.

*1 Based on our own research(As of Nov. 2022)

Data Integrity (DI) required mainly in the pharmaceutical

Following the European trend of Industry 4.0, quality assurance management has become stricter, especially in the pharmaceutical industry.This trend calls for instruments like 「Paper and electronic data/Can always be proven correct subject to the record」 in measuring instruments as well.In the example of the pharmaceutical industry, ensuring the ALCOA principle is a DI requirement.The following are required as assurance of the reliability of clinical trial data, etc. In recent years, there has been a movement to add more positive items.

[ALCOA Overview]

[A] Attributable: The source is clear (Signature, Login ID)

[L] Legible: Readable/understandable (Legibility)

[C] Comtemporaneous: Simultaneous with business (Prompt record)

[O] Original: The original (Save/Store, Review)

[A] Accurate: Accurate (Date, time, calibration and validation)

"Maxxis Series PR5500/PR5900" DI compatible

Our weighing systems are DI compliant and come standard with the following features to support your data integrity

・User permissions (3 levels of permissions)

・Password management (individually configurable)

・Audit trail management functions (partial)

・Data backup function (data export to USB/SD memory)

・Restore function (restore calibration data and setting data)

・Printing (operate the print application key)

・Time synchronization with server

In particular, it has been difficult to manage and check the operating authority of equipment users for weighing indicators, and we have been particular about "user authority," which has been requested by many of our customers. The "Maxxis PR5500/PR5900" has a three-tier user management function that enables logging of "who", "when", and "which amount of weight" has been weighed.

①Administrator (manages all permissions)

②Supervisor (omitting some authority from the manager)

③Operator (dedicated only to weighing operations)

"Maxxis Series PR5500/PR5900" Database Storage

SD card and USB memory stick inserts are standard for easy copying and backup of calibration data.

・Software fixes and updates

・Output weighing results to USB

・Save all configuration data and databases

"Maxxis Series PR5500/PR5900" system example

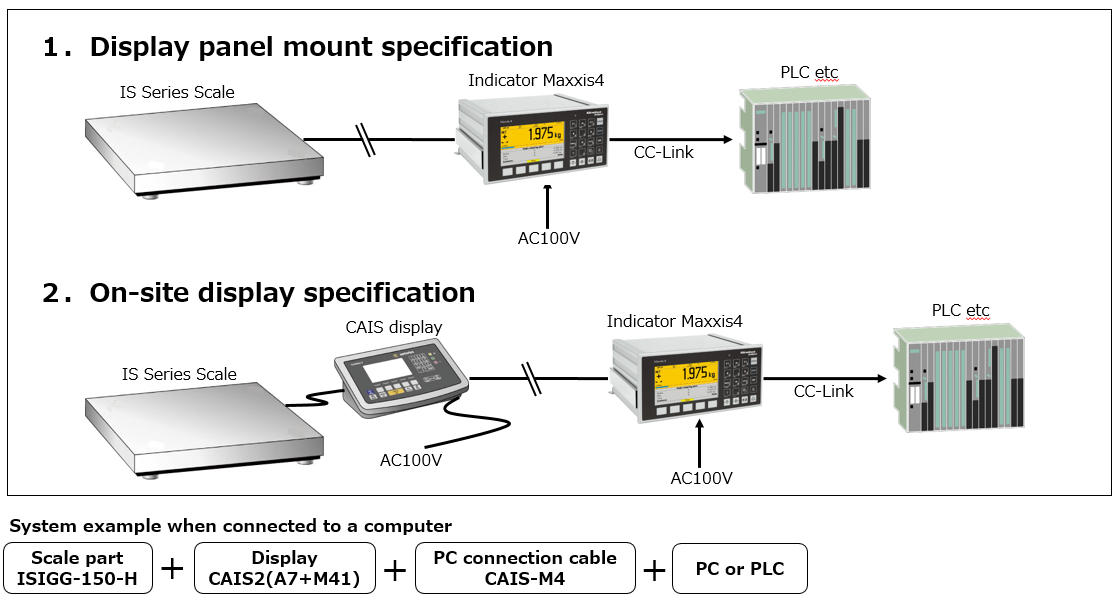

Platform scales system example

Tank weighing system example

* Application-1

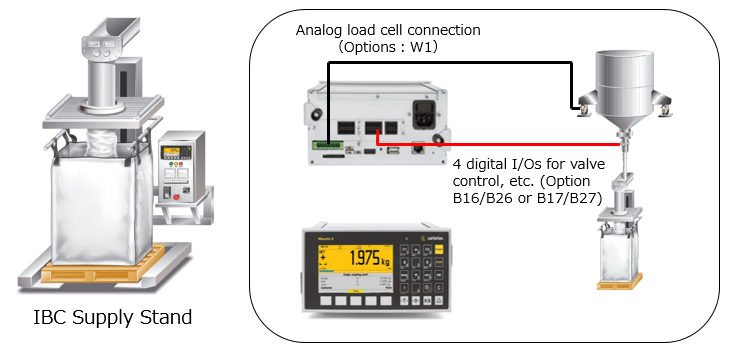

In addition to the use of general measuring instruments, it can be used for different applications.

Example: Filling weighing system

* Application-2

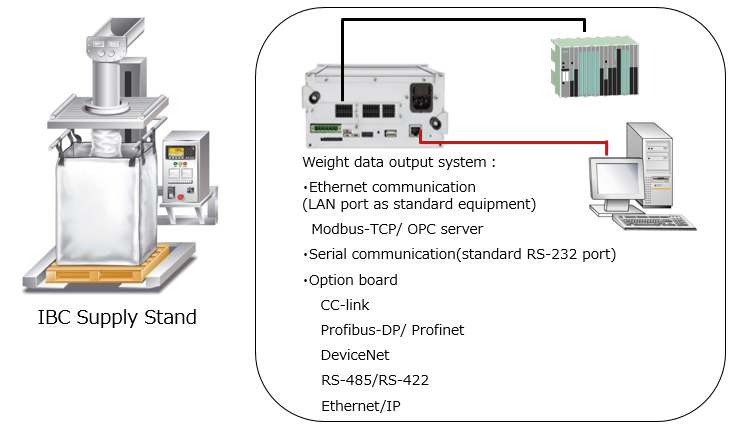

When weight data is deployed to a host system, Ethernet communication, serial communication, etc. can be selected.

Example: Filling weighing system

Link to product page

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.