Functions / Technologies

We have compiled frequently asked questions from our customers and their answers.

Please use this if you cannot find the information you are looking for or need more detailed information.

Product Category

-

*Search example : Stator Ass'y, Rated Torque

Bearings

Miniature & small ball bearings

QHow can I find the grade of the ball bearing from P/N information?

AEngineering Information

QHow much is the rotation torque range?

AEngineering Information

QI would like to know maximum axial load of the ball bearing.

A

QI would like to know radial, axial and angle clearance of the ball bearings.

A

QI would like to know the tolerance of shoulder diameter(Lo/Li).

A

QI would like to know the tolerance of the shaft and housing in the case of tight fitting.

AEngineering Information

QI would like to know the difference of internal design "X2", "X3" etc…

A

QI would like to know the weight of ball bearing.

A

QI would like to know chemical, acid resistant ball bearings.

A

QI would like to know useful temperature range of ball bearings.

A

QI would like to know about low-outgas grease information.

A We have a various grease of your requesting cleanliness.

We can recommend the best low-outgas grease for your requesting cleanliness and applications.

QI would like to know the difference of the P/N "608ZZ" and "R-2280HH".

A

Precision Machined Components

Precision mechanical components

QWhat is PMC?

A

Fastener

QWhom should I ask about technical question?

A Please contact your sales representative or submit your query via our Contact form.

QPlease tell me size variation of fastener.

A We will consider the size of the production of customer requirements. Please contact us for details.

QWhat kind of raw material is used for your products?

A We manufacture parts for a variety of materials including aluminum alloys , titanium alloys , alloy steels, etc. I have experience in a wide variety of materials In addition to this, more details, please contact us.

QWhat kind of surface treatment can you process?

A Minebea can perform virtually all of the surface treatment required for fasteners and mechanical parts, such as cadmium plating, silver plating, hard chrome plating, zinc plating, and others. Please contact us for details.

QWhat kind of heat treatment can you process?

A In order to ensure the product characteristics required by consensus or customers' standards , Minebea has a full line-up of heat treatment equipment, including vacuum furnaces, continuous-type furnaces, and shaker hearth furnaces for titanium alloy fasteners . Please contact us for details.

Wavy Nozzle

QWhere are the control boards stored?

A The control board is stored inside the machine control panel box.

QIs it possible to set the operation mode without a controller?

A A controller is required to set the operation mode. It can be set with a wired controller or a wireless controller using an iOS device.

QIs it possible to set the operation mode from NC?

A No. A controller (wired or wireless connection) is required.

QCan a non-NC machine use Wavy Nozzle?

A Yes, it can also be controlled by a Sequencer.

QIs there any influence of noise caused by other devices in the factory when connected via Bluetooth?

A Normally, Bluetooth can communicate over a distance of 20 meters (65 ft), but the it has been verified to be able to communicate if it is 5 meters (16 ft) in a factory noise environment.

QIs there a standard lineup of attachments (mounting jigs)?

A A standard installation kit is currently available only for FANUC ROBODRILL. However, for other machines that have a track record of installation with MinebeaMitsumi, jigs have been made into drawings and it is possible to buy mounting jigs and obtain drawings.

We can sell mounting jigs and provide drawings.

QCan Wavy Nozzle use for Semi-dry cut using oil mist?

A Yes. It can be used.

QWhat is the maximum viscosity of the cutting-oil?

A We have experience of up to 40mm2/s viscosity.

QWhat kind of coolant can be used?

A Wavy Nozzle can be used by oil based coolant WITHOUT chlorine or active sulfer and water based coolant WITH mineral oil.

If you want to use other kind of oil, please inquire from the form.

QCan Wavy Nozzle eject air instead of coolant?

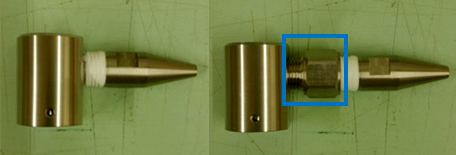

A Currently there are two types of nozzles with dia. 3mm and dia. 5mm holes. Since the nozzle is attached by a 1/4 tapered screw, it can be replaced with a commercial nozzle.

QCan Wavy Nozzle use any other liquids besides coolant oil? For example, cleaning solution.

A Use with liquids other than coolant is not covered by the warranty. However, since some liquids may be usable, please consult with the manufacturer and model number of the liquid.

QIs the M-code signal used to operate Wavy Nozzle a "shot signal" or "Latch Signal"?

A Latch signal is required.

QIs it possible to change the cable between the ejection unit and the control board to longer cable?

A No.Operation is guaranteed with the product cable length of 6 meters (20ft). If the cable is extended, it cannot be guaranteed. If the length is not enough, divide the control board and extend it with a cable.

QThere are 5 M-code inputs with the standard setting. How can it be expanded up to 31 settings?

A By changing M-Code process mode to "5-BIT", the 31 settings can be called up by combination of 5 codes on a single input line.

QKICK mode has a function of oil ejection of one-direction. Does Wavy Nozzle have a built-in valve?

A No, Wavy Nozzle does not have a valve itself, but it can control the ON/OFF valve signal in the machine.

QHow are air and oil connected?

A An existing nozzle(s) is typically removed and replaced with a Wavy Nozzle unit. An existing or new coolant line would need to attach to the Wavy Nozzle. An adapter may be necessary.

QHow to wire Nozzle cable?

A Nozzle cable is routed using existing holes inside machining area.

QWhat is the oil inlet of the ejection unit?

A Rc3/8 female (BSPT)

QCan discharge pressure be adjusted?

A No. There is no valve or pressure-increasing function inside the Wavy Nozzle, and the pressure of the pump dominates the discharge pressure because it is just a flow path.

QIs there any limitations regarding the mounting direction?

A There is no limit, as any position/orientation will not affect its ability to operate.

QCan we buy a mounting jig?

A Standard mounting jigs can be supplied as drawings. They can also be sold (extra cost).

QCan we obtain CAD files to consider installation?

A Yes, CAD files can be provided.

QIs it necessary to connect the controller even during operation?

A No. The controller is needed only for setting up the operation mode. Once the setting is complete, there is no problem in operation, even if the controller is removed.

QIs there an alarm signal output that informs the failure of Wavy Nozzle to the machine?

A Yes. An alarm output terminal is provided on the control board. You can respond by connecting the wiring from the control board to the machine and adding it as an alarm condition or a stop condition. Connection and NC setting is needed.

QIs there the function that notifies the Wavy Nozzle when the machine stops or has an alarm signal?

A Yes. There is an External alarm input terminal in the control board.

QIs there a case where all coolant is processed only with the Wavy Nozzle?

A Yes. But, depending on the situation not all processes can be covered with just a single Wavy Nozzle. In that case, please use a fixed nozzle together.

QAre there any variations of the nozzle available?

A Currently there are two types of nozzles with dia. 3mm and dia. 5mm holes. Since the nozzle is attached by a 1/4 tapered screw, it can be replaced with a commercial nozzle.

QDo chips clog inside Wavy Nozzle?

A If chips larger than the nozzle diameter enter, they will clog. If clogged, remove the nozzle and blow with air to remove chips.

QDoes vibration of the nozzle's movement affect accuracy?

A From our experience in precision machining at MinebeaMitsumi, it is not a problem as long as the Wavy Nozzle unit is mounted tightly.

QHow to troubleshoot error codes?

A Please check the diagnostic chart.

QWhat is the solution when coolant pressure drops?

A Please clean the filter and coolant tank.

QCoolant stream is scattered and diffused, and is difficult to spray at the desired cutting point.

A Attach a flow straightening adapter to the nozzle.

QWhat is the countermeasure for the limited installation space that prevents injection at the cutting point?

A Install a variable angle nozzle. It increases the range of injection positions.

QWhat is the difference from the high pressure coolant system?

A High-pressure coolant equipment forcibly breaks chips with high-pressure cutting oil injection of 10 to 20 MPa. The Wavy Nozzle allows the chips to extend and flow in one direction. The chips are not necessarily broken. In the following cases, try using a Wavy Nozzle:

Rotary Components

Electromagnetic Clutches and Brakes

QCan I ask technical questions here?

A Please use the Conract form and make sure to include the model number.Engineering Information

QCan you select clutches and brakes for us?

A Yes, but we'll require detailed usage conditions. For details, please contact your sales representative or submit your query via our Contact form.

Fan Motors

AC fan motors

QAre there any restrictions for mounting method about fan motor?

A Since ball bearings are used for the bearings, the mounting can be selected horizontally, vertically, or tilted.

DC fan motors

QAre there any restrictions for mounting method about fan motor?

A For either the suction or the exhaust type, horizontal, vertical or inclined installation can be selected. However, some models have a limited mounting direction. In that case, please check the specifications as "mounting attitude".

QPlease tell me protection method when blade is locked.

A Motor burnout is prevented by the current cut-off automatic restoration function.

QPlease tell me connection method.

A We connect lead wires[red:+,black -] from fan motor body to DC power supply with specified voltage.

QPlease tell me how to choose "with ribs" or "without ribs".

A We select "with ribs" when fix frame through and "without ribs" when fix on one side of flange.

DC blower fan motors

QPlease tell me protection method when blade is locked.

A Motor burnout is prevented by the current cut-off automatic restoration function.

QPlease tell me connection method.

A We connect lead wires[red:+,black -] from fan motor body to DC power supply with specified voltage.

High-pressure blowers

QCan I ask technical questions here?

A Please use the Conract form and make sure to include the model number.Engineering Information

QWhat power supplies do we need?

A The drive circuits require an AC power supply: 200 V (-475, -477, -478 models) or 100 V (-478 model); the signal circuits, a DC power supply: 0-10 V.

QHow do we install and connect?

A Please refer to the Instruction Manual for instruction.

QCan you supply blowers alone?

A No, only as sets.

QWhat is the service life?

A The warranty is for one year or 5,000 hours.

A product's service life depends on the customer's usage conditions.

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.