What is a pressure sensor?

What are the types and features of pressure sensors?

Classification by pressure reference is also explained

Pressure sensors are measuring instruments that measure the pressure of fluids such as oil, water and gases flowing through pipes and equipment, and various types are available depending on the differences in measuring principles.

Specific pressure sensor types, features and applications are outlined here, along with the features of MinebeaMitsumi's products.

1. What is a pressure sensor?

A pressure sensor is a type of force sensor that measures the pressure of liquids or gases such as oil, water or gas flowing through pipes or inside equipment.

There are several measurement principles used for pressure sensors, but the basic principle is that pressure is calculated by measuring the strain generated, by applying pressure to a metal part mounted to the pressure receiver of the pressure sensor.

See here as well

What is a force sensor? Explanation of types, applications, and measurement principles

Pressure sensor applications

Pressure sensors are used in a variety of situations. For example, they are used in the following applications when measuring fluids flowing through pipes and equipment.

<Main pressure sensor applications>

- Pressure measurement of compressors and chillers

- Water pressure measurement at hydroelectric power plants

- Hydraulic equipment at factories, etc.

- Amount of boiler steam for steam generation

- Confirmation of gas tank level for carbonic acid production

- Hydraulic measurement of construction equipment and special vehicles

- Gas combustion pressure measurement

- Injection molding machines

- High-pressure sterilization equipment

They are also used to measure the air pressure of soccer balls, basketballs, tires, and other items in familiar situations.

One place in particular where MinebeaMitsumi's pressure sensors are used is in the space industry, a symbol of the high-tech sector. Japan's first domestically produced rocket H-II A/B is equipped with about 60 MinebeaMitsumi pressure gauges, which are used to measure the tank pressure and combustion pressure of liquid oxygen and liquid hydrogen.

They were also used on the H-II Transfer Vehicle (HTV), also known as Kounotori, which was used to carry supplies to the International Space Station (ISS).

It should be noted that the pressure gauges used in these rockets and spacecraft were not custom-made items. We supply products manufactured on the same lines as those sold to our general customers.

2. Features of MinebeaMitsumi's pressure sensors

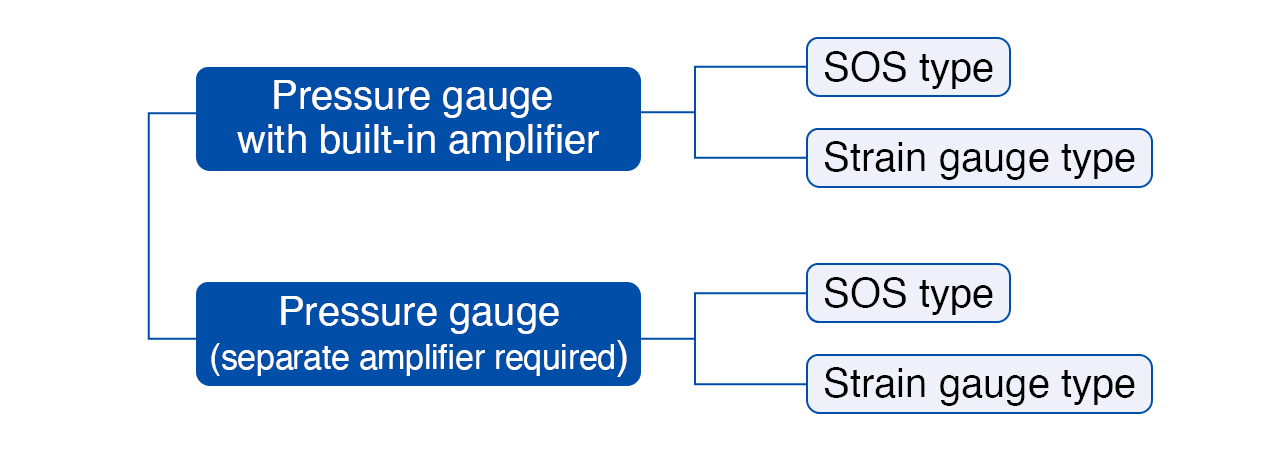

MinebeaMitsumi pressure sensors are currently separated into two types: those with built-in amplifiers, and those requiring separate amplifiers. They can be further separated into the "SOS type" and the "strain gage type" depending on the material that sensitive components are made of.

The SOS type is a strain gage formed by crystallizing a thin film of silicon onto a sapphire (Al2O3 single crystal) substrate, which is an insulator, using the Silicon On Sapphire (SOS) technology, and processing it into a silicon semiconductor.

These silicon semiconductor strain gages function as extremely stable pressure sensors, both physically and electrically, because the electrical resistance lines themselves are atomically bonded to the sapphire substrate. Their features are as follows.

<Features of silicon semiconductor strain gages>

- High responsiveness

- Long-term stability

- High precision

The features of MinebeaMitsumi's pressure sensors in each of the sub types are outlined here.

Features of pressure sensors with built-in SOS type amplifier

The "NS100A" pressure sensor mounted on the H-II A/B launch vehicle is a pressure sensor with a built-in SOS-type amplifier. Accuracy is 0.2%R.O. (0.1%R.O. is also possible), and negative pressure (compound pressure) and absolute pressure can be measured, although there are some differences depending on the product.

Main applications include automatic transmission test equipment, air conditioning test equipment, precision machine pneumatic operating controls, various test benches for rolling stock, and rockets.

Features of strain gage type pressure sensors with built-in amplifier

Strain gage type pressure sensors with built-in amplifier are equipped with an ASIC amplifier and use a strain gage with a low current consumption of 20 mA or less. ASIC is an acronym for "Application Specific Integrated Circuit" and refers to an IC (semiconductor integrated circuit) with dedicated functions for specific applications.

With a dedicated IC like this, the electrical circuit is extremely insensitive to external noise components. They are also characterized by their resistance to temperature, with specifications of ±1.0% F.S./-20 to 70°C.

They also have mechanically superior construction and materials. The pressure sensitive components maintain fatigue resistance due to the integral construction of the pressure inlet and machined stainless steel alloy. In-house evaluation tests of 1 million cycles at 150% F.S. pressure achieved an amount of change before and after the test within ±0.3% F.S.

MinebeaMitsumi's strain gage type pressure sensors with built-in amplifiers demonstrate high accuracy and high stability, and are used in injection molding machines, press machines, various pump systems, and hydraulic equipment.

What is a strain gage? Explanation of how it works, types, and points for selection

Features of SOS type pressure sensors

SOS pressure sensors can measure negative pressure (compound pressure) and absolute pressure, and are characteristic in that they are capable of measuring the negative pressure side with high accuracy. Accuracy is 0.2%R.O. for standard specifications and 0.1%R.O. for high-precision specifications.

The temperature compensation range is -20 to 120°C for general applications and -40 to 150°C for special specifications, allowing measurement of high and low temperature fluids. Furthermore, when combined with a high-response transmitter, measurements can be taken approximately five times faster than normal.

Features of strain gage type pressure sensors

Like SOS type pressure sensors, strain gage type pressure sensors can also measure about five times faster than normal when combined with a high-response transmitter. They are suited to a broad range of pressures from 1 to 100 MPa. They also come with a drain cock (exhaust plug) for venting air.

MinebeaMitsumi currently has a line-up comprising five products, which are robust, have excellent long-term stability and can be used in a wide range of applications. They are used in presses, various chemical plants, high-viscosity fluid equipment, automotive onboard testing, depth monitoring equipment for fisheries, hydraulic equipment for cranes, and transmission testing equipment for construction machinery.

3. Pressure sensor classification with method taken for pressure reference

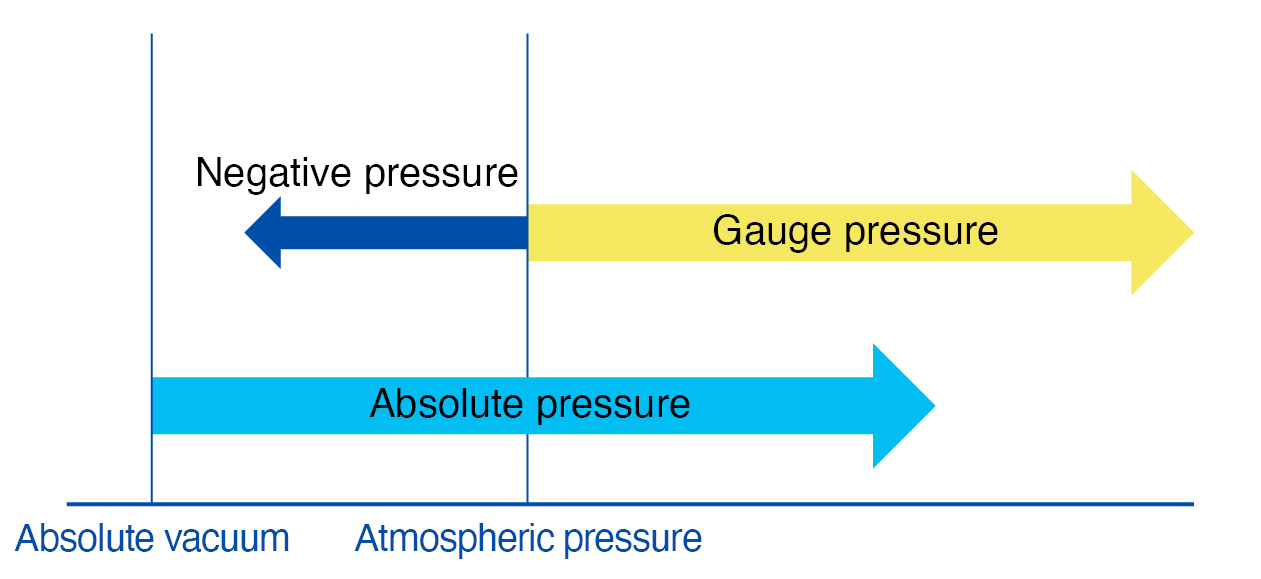

MinebeaMitsumi's pressure sensors are separated into "absolute pressure type" and "gauge pressure type" according to the method taken for the pressure reference.

Absolute pressure is the pressure based on an absolute vacuum, i.e., zero atmospheric pressure with no molecules at all present in the atmosphere.

In contrast, gauge pressure is the pressure measured with respect to the current atmospheric pressure. Negative pressure refers to pressure that is lower than the current pressure. Pressure sensors measuring positive gauge pressure are called pressure gauges, and those measuring negative gauge pressure (negative pressure) are called vacuum gauges.

4. Selecting the appropriate pressure sensor for the application is crucial

A pressure sensor must be selected that is appropriate for the application, or not only will it result in incorrect measurements, but it may also interfere with running and operation—in the worst case, an incorrect sensor may cause damage to equipment or a serious accident or disaster. Thus when selecting a pressure sensor, the application must be considered properly.

Other factors for selecting pressure sensors include the following.

<Major selection factors for pressure sensors>

- Type of object (oil, water, air, nitrogen, oxygen, acetylene, propane, etc.)

- Type of pressure sensor (gauge pressure type, absolute pressure type)

- Pressure sensor measurement method

- Pressure sensor size

- Operating pressure range

- Required measurement accuracy

5. If you need a pressure sensor, contact MinebeaMitsumi and inquire about our extensive product lineup.

There are various types of pressure sensors available for each application, measurement method, and accuracy.

MinebeaMitsumi has experts who are familiar with pressure sensors and can provide suggestions on what kind of pressure sensor to select. If you are seeking to deploy pressure sensors, do not hesitate to send us an inquiry.

For product-related inquiries, please contact us using the form below.

Related page

Engineering Information for Pressure Sensor

Basic Knowledge

Technical Data

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.