What is an IC (integrated circuit)?

What is an IC (integrated circuit)? Explanations of its basic structure, manufacturing process, application examples, and more

Integrated circuits (ICs) are semiconductor products that play an important role in electronic devices.

This article explains the basic structure of ICs, their manufacturing process, the differences in their

applications by function, and others in a way that is easy to understand. Let's also take a closer look at

current trends and future prospects.

1. Basic structure of an integrated circuit (IC)

ICs are semiconductor products that are essential for controlling, processing and storing information in electronic devices.

An IC has a structure in which a circuit comprising semiconductor devices such as resistors, capacitors, and transistors are integrated into a single small chip, and is also called an “integrated circuit.” There are various types of ICs, such as power supply ICs, motor ICs, data converter ICs, amplifier ICs, and memory ICs, and they are used differently depending on the application.

2. High integration of ICs and Moore's Law

As technology has evolved, semiconductor devices have become progressively smaller, and the number of devices that can be integrated into an IC has continued to increase year after year. Gordon Moore, one of the founders of Intel, a major semiconductor manufacturer, predicted in 1965 that the density of semiconductor integration would double every 18 months, and this is known as Moore's Law.

The trend toward higher integration in ICs has progressed as Moore predicted, and large-scale integrated circuits, such as LSIs, are now commonplace. However, the miniaturization of semiconductors is approaching its physical limits, and some say that the “post-Moore era” will arrive once we reach the limit of density.

On the other hand, there is also the argument that Moore's Law will continue, albeit at a slower pace, and one of the factors is that the improvement in density is not coming from miniaturization, but from 3D integration, that is, in a 3D layout. In addition, it is not density but energy efficiency that is seen as the new benchmark for the evolution of ICs, and recent years have seen a remarkable improvement in energy efficiency.

3. IC manufacturing process

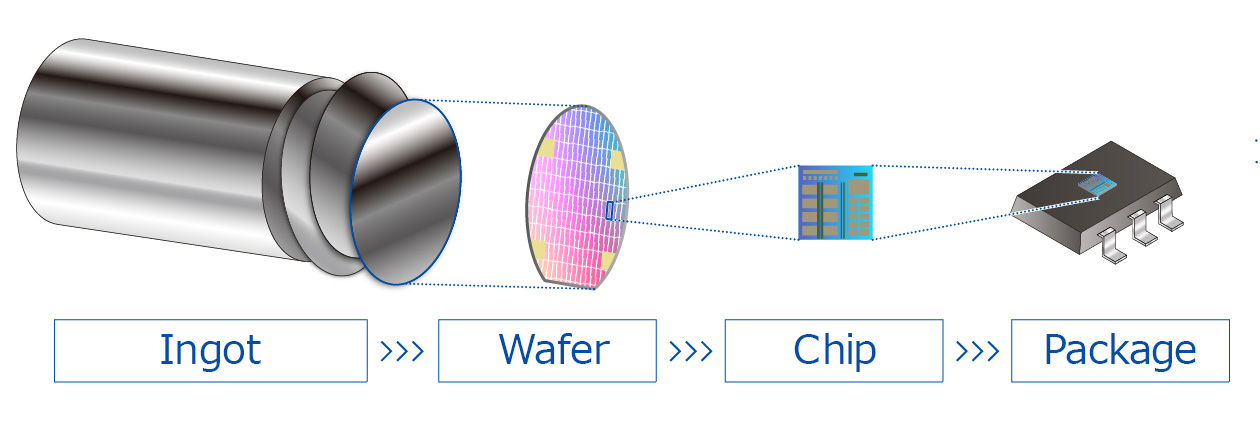

ICs are tiny electronic components, and this section introduces the general manufacturing process for ICs.

1. Creating wafers

First, an ingot—a cylindrical block of silicon—is sliced thinly with a wire saw or similar device. The thin circular plate created in this way is called a “wafer” and is the base for the chip.

2. Deposition

After the wafer is deburred, polished, and cleaned, it is exposed to high-temperature oxygen to oxidize the surface and form an oxide film that acts as an insulating layer. It is also possible to form other thin films by using substances other than oxygen. This process is called deposition.

3. Photolithography

Photolithography (exposure) is the process of forming the circuit patterns designed and created by computer on the deposited wafer. First, a circuit pattern is transferred by exposing a wafer coated with a photosensitive agent called photoresist to ultraviolet light or other light to make it photosensitive.

The unexposed areas are then removed by dipping the wafer in a developing solution or the like, or the exposed areas are removed to expose the circuit pattern.

The method of removing the unexposed areas is called negative photolithography, and that of removing the exposed areas is called positive photolithography, and they can be used differently depending on the type or purpose of the IC to be manufactured.

4. Etching

Etching is the process of removing unnecessary parts such as oxide films and thin films that have been exposed by photolithography. The two main methods are “wet etching,” which uses chemical liquids such as acids and alkalis, and “dry etching,” which uses ions. The method used depends on factors such as cost, productivity, and processing accuracy.

After etching, further polishing is performed.

5. Doping

Doping is a process that changes the electrical characteristics of the wafer. Wafers made of pure silicon are insulators, so electricity will not flow through them as they are. Therefore, impurity ions called dopants are added to allow electricity to flow through certain regions of the chip. Doping may also be performed during the deposition process described above.

Note that the process from deposition to doping is almost always repeated dozens of times.

6. Forming the electrodes (metallization)

Next, electrodes are formed on the wafer. There are two methods for this: one is to form a thin metal film on the surface of the wafer using a technique called sputtering; the other is to embed metal parts in the wafer.

7. Dicing and packaging

The process of cutting the IC chips on the wafer one at a time is called “dicing.” The chip is then fixed in a metal frame called a lead frame and connected to gold wires. It is then packaged in resin to protect the chip, and the process is complete.

4. The main methods of IC classification

There are many types of ICs, and because their functions and applications vary widely, there are many ways to classify them. This section explains the main classification methods.

Classification by the number of semiconductor devices

ICs can be categorized according to the number of semiconductor devices integrated into the chip. They are classified from smallest to largest as follows: small-scale integration (SSI) (fewer than 100 devices); medium-scale integration (MSI) (100 to 999 devices); large-scale integration (LSI) (1,000 devices or more); very large-scale integration (VLSI) (1 million devices or more); and ultra-large-scale integration (ULSI) (10 million devices or more).

Note that an example of the application of highly integrated ICs such as LSIs, VLSIs, and ULSIs are the

microprocessors and GPUs installed in PCs.

Classification by function and application

ICs can be classified into three types according to their functions and applications: analog ICs, digital ICs, and mixed-signal ICs. Their main functions and applications are as follows.

Analog ICs

Analog ICs process continuous analog signals. They are used for amplifiers, filters, power management, and so on.

Digital ICs

Digital ICs process digital signals. They are used in memory and the CPU, which are the heart of the computer.

Mixed-signal ICs

Mixed-signal ICs are capable of processing both analog and digital signals. They are used in cell phones and automobiles.

Classification by structure

ICs can also be classified according to the difference in their structure. There are two main types: the planar type, which has a flat structure; and the non-planar type, which has a three-dimensional structure.

In addition, the non-planar type can be divided into the FinFET type, which has a three-dimensional structure and is more compact than the planar type, and the Gate All Around (GAA) type, which has an even more complex structure than the FinFET type and is extremely efficient in terms of power consumption.

5. IC application examples

It is no exaggeration to say that ICs are used in almost all of the electronic devices and mechanical equipment that enrich our lives and businesses. And as these electronic devices and technologies evolve, so do ICs. This section introduces some of the particularly notable areas of IC application examples.

Lithium-ion secondary batteries

There are two types of lithium-ion batteries: primary batteries, which cannot be recharged once they have been discharged; and secondary batteries, which can be recharged and used repeatedly. A special IC for ensuring the safe use of the latter, rechargeable lithium-ion secondary batteries, is the “lithium-ion battery protector IC.”

Lithium-ion secondary batteries are rechargeable and have a higher energy density than conventional rechargeable batteries, allowing them to be smaller and lighter. They are used as power sources for smartphones, digital cameras, home storage batteries, electric vehicles (EVs), and more.

To ensure such batteries operate safely, it is necessary to control overcharging, overdischarging, and sudden temperature changes. When the lithium-ion battery protector IC detects these conditions, it automatically stops the lithium-ion secondary battery charging or discharging.

IoT

Sensing technology is essential for IoT devices such as smart homes and wearable devices, and ICs are also indispensable for such sensors.

In addition, IoT devices require long-lasting power supplies, autonomy, and high precision, and the expectations and demand for power supply ICs are increasing more than ever.

Artificial intelligence (AI) and machine learning

Recent years have witnessed the evolution of artificial intelligence (AI), especially generative AI, which is capable of large-scale machine learning and output. The number of scenarios in which it is used is increasing, and ICs are central to such applications. This is because in machine learning and generative AI, GPUs play a particularly important role in processing large amounts of data, and both GPUs and CPUs are types of ICs. And as the volume of data increases, so too does the amount of power consumed, making the role of power supply ICs crucial.

6. When it comes to your analog IC needs, talk to MinebeaMitsumi. We can integrate all processes from development to production.

ICs lie at the heart of all electronic devices and are an area that is destined to keep evolving in the future. In light of this, various semiconductor manufacturers are continuing their research and development to achieve technological innovation.

In response to this social background and demand, MinebeaMitsumi handles a variety of analog ICs for various applications, including power supply ICs, motor ICs, data converter ICs, and amplifier ICs. If you have any problems or questions about these ICs, please feel free to contact us.

Click here for technical questions, requests for various materials, etc.

Related page

Engineering Information for Semiconductors

Basic Knowledge

Technical Data

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.