Features

Achieves "demodulation-less" motor control that does not stop even with a high load or rapid acceleration/deceleration is applied, providing smooth operation with a resolution of 200,000 P/R.

The simple structure of the resolver also contributes to durability against the outside environment. Robust manufacturing supports a motor drive with extremely stable accuracy in harsh environments such as heat, dust, shock and vibration.

Specifications

| Model | Outer Diameter [mm] |

Length [mm] |

Step Angle [°] |

Drive Sequence | Rated Current [A] |

Resistance [Ω] |

Holding Torque [mN・m] |

Inductance [mH] |

Rotor Inertia [g・cm2] |

Detent Torque [mN・m] |

Mass [g] |

|---|

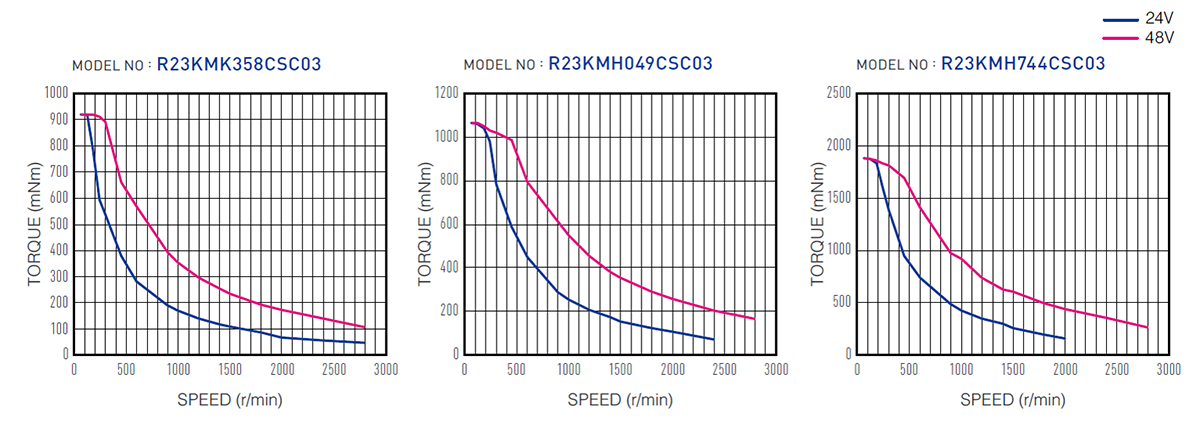

Torque/Speed Characteristics

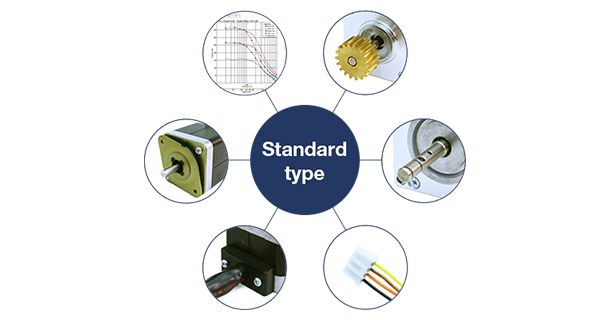

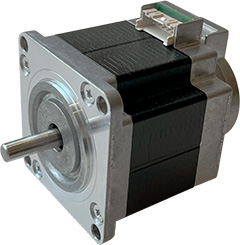

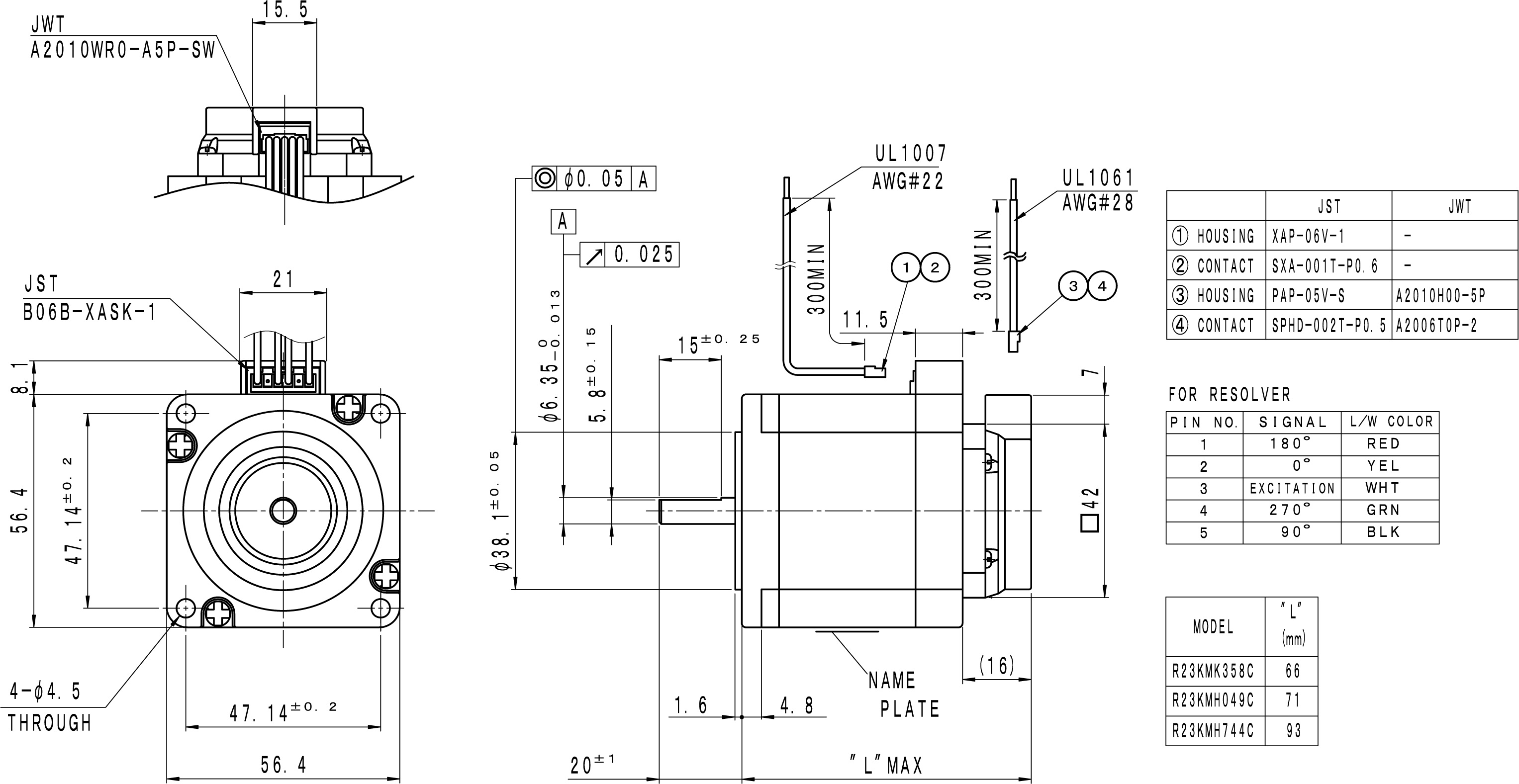

Overall View

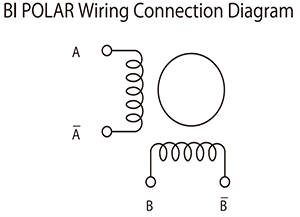

Wiring Diagram Image

Wiring Diagram

| PHASE | A | A COM | A/ | B | B COM | B/ |

|---|---|---|---|---|---|---|

| PIN NO. | 3 | - | 1 | 4 | - | 6 |

Guidance

To control the stepping motor with resolver, Digital converter (RDC) from Renesas Electronics Corporation And control driver software is required. For details, please see the link below.

Download

Associated Data

Product customizations by MinebeaMitsumi

We customize products through technological consultations, sample productions, optional functionalities, and other forms of support we offer to meet your demands.