Wavy Nozzle installation method

Setting the injection position

Outside diameter cutting

Adjust so that the cutting oil is sprayed to the point where the tool and material touch.

Internal diameter cutting

Chip winding around by shaking the nozzle so as to remove the chips coming out from the inner diameter.

Back cutting tools

Pressure does not drop because coolant is discharged to each tool.

Chips are removed by spraying coolant while swinging the nozzle.

* For fixed coolant nozzles, the coolant pressure typically drops because the line is branched for each tool in the back operation.

Machining center

* Please refer here for the mode setting for the machining center tool.

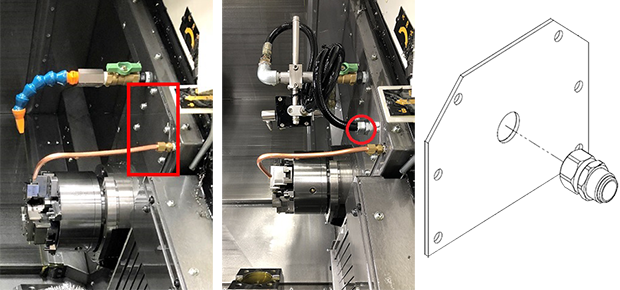

Installation of Ejection Unit

Install to the machine by using mounting bracket

Basic: Install by using existing screw holes

* Drawings can be provided. Please contact us.

|

Machine type |

Machine manufacturer |

Model |

Injection point |

Photo |

|

|---|---|---|---|---|---|

| Gang type automatic lathe | TSUGAMI | SS327 | Back operation tool | 1 | |

| CITIZEN MACHINERY | L12 | Main spindle | 2 | 2-A | |

| CITIZEN MACHINERY | L20 | Main spindle | 3 | ||

| STAR | SR-32J | Main spindle | 4 | ||

| Turret type automatic lathe | YAMAZAKI MAZAK | QUICK TURN 200 | Main spindle | 5 | |

| TAKAMAZ | XD-10 | Main spindle | 6 | ||

| CITIZEN MACHINERY | BNA-42GTY | Main spindle | 7 | ||

| Machining Center type | FANUC | ROBODRILL | Main spindle | 8 | 8-A |

Installation · Setting · Adjustment movie on machine

Nozzle cable placement method

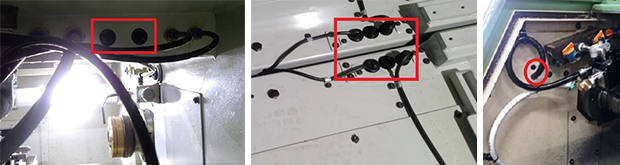

Through hole in the cutting area of the machine

If there is a through hole in the machine, pass the nozzle cable out of the machine and connect to the control board of the Wavy Nozzle.

No through hole in the cutting area of the machine

If there is no through hole in the machine cutting area, there is a plate that can be opened during maintenance work, so replace the plate with a through hole added or a new plate.

Pass the nozzle cable outside the machine and connect to the control board of the Wavy Nozzle.

Recommended coolant pump pressure

Maximum discharge pressure of Wavy Nozzle: 4MPa

* Wavy Nozzle initial type (WN-01 / WN-02) is 2MPa.

Recommend coolant pump pressure

Oil-based coolant: 1 - 4 MPa

Water-soluble coolant: 0.3 - 4 MPa

1 MPa = 10bar = 10.2kg / cm2 ≒ Total head 100m

If discharge pressure of the coolant pump is low, coolant injection will not be straight, so the swinging motion of the Wavy Nozzle will not be effective.

If output of the coolant pump is branched and they are injected at the same time, the injection pressure from the Wavy Nozzle will drop.

For effective use of the Wavy Nozzle, it is recommended to turn OFF other coolant injections.

For machining centers when using water-soluble coolant, a normal pump may be effective.

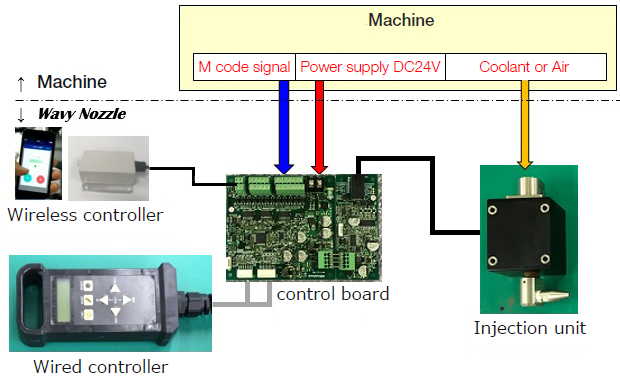

Wavy Nozzle connection diagram

Wavy Nozzle connection* Basic connection to the machine

* The wireless controller is not compatible with the initial type (WN-01 / WN-02) of Wavy Nozzle.

Electrical wiring

Latch Signal M-code

Operation command: Operation memory call by M-code

Wavy Nozzle starts operation when it receives an M-code signal from the NC unit.

Wavy Nozzle has 5 operation command input terminals and can save up to 31 settings.

The M-code that Wavy Nozzle can use is one that can be "Latch Signal operation". (i.e. once turned ON, it remains in the ON state until it is turned OFF.)

e.g.) Nozzle operation command at Y100 terminal that can be turned ON / OFF with M-code M8 / M9

Example of electrical wiring diagram

Please refer here for an example of an electrical wiring diagram.

- Example of electrical wiring diagram

- * Wavy Nozzle initial type (WN-01 / WN-02) has a different wiring method.

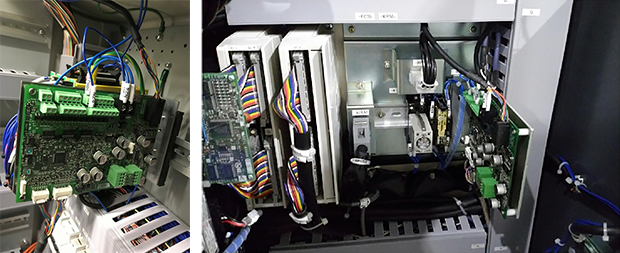

Example of control board installation

The control board of the Wavy Nozzle is stored in the control box of the machine.

- "Wavy Nozzle" is registered trademark of MinebeaMitsumi Inc.

Japan registered trademark : No. 5645210 - "FANUC" and "ROBODRILL" are trademarks or registered trademarks of FANUC Corporation

- iOS is a trademark or registered trademark of Cisco in the U.S. and other countries and is used under license.

- The Bluetooth word mark and logos are registered trademarks owned by the Bluetooth SIG, Inc.

Related page

Engineering Information for Wavy Nozzle

Technical Data

Contact Us

Please click the inquiry type below according to your question. Each product / sales representative will respond to you.